Features/Functions

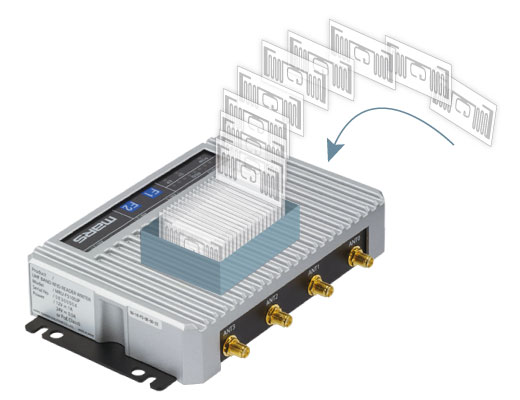

The MRU-F5100JP is an easy-to-configure, autonomous UHF RFID fixed reader/writer.

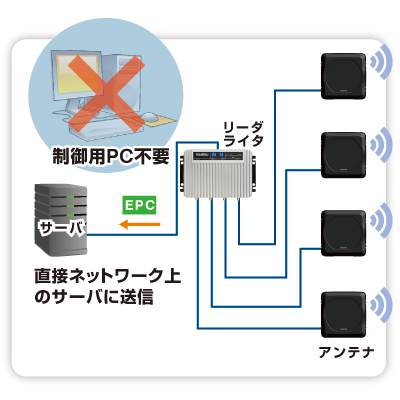

Autonomous operation reduces upper-level system development (autonomous mode)

The unit automatically takes a reading and transmits the data when the power is turned on.

Various settings can be made via a browser.

There is no need to run a complex program from a PC or other device.

Data can be sent not only to a server on the LAN, but also to a cloud server on the Internet via a router.

The server side can receive data via a web server, etc. Secure communication is possible using HTTPS.

System developers can easily start a system using RFID reader/writers.

Supports a wide range of communication methods

LAN and serial interfaces plus DIO.

Capable of receiving digital inputs from sensors and digital outputs to peripheral devices.

Number of antenna ports: 4.

Flexible DIO collaboration

For each of the four digital inputs, it is possible to set which antenna is used and how many radio outputs are used. This allows a variety of readings to be made depending on the situation. (In autonomous trigger mode)

Supports LAN connections (socket and HTTP/HTTPS communication)

HTTP/HTTPS communication supports the GET and POST request methods and the JSON method.

Compact, space saving, PoE compatible, choice of antennas

Compact size and PoE compatible. The antenna can also be changed to suit your needs, providing a highly flexible installation. A variety of connector configurations can be selected to suit the application.

High robustness and reliability to withstand hard industrial applications

Robust design. Operating temperature -20 to +55°C for use in cold to hot environments. Supports RS-232C communication and wired LAN. Ideal for use in production environments where ruggedness and reliability are required.

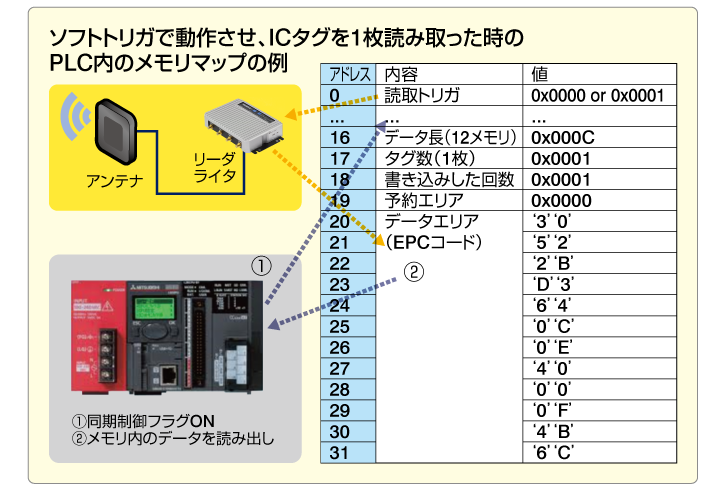

PLC link function

The PLC Link function writes the IC tag data to memory in the PLC simply by setting it up.

There is no need to set up a ladder to send complex commands.

A trigger from the PLC or a sensor etc. is used to trigger the reading detection of the IC tag, and the IC tag data is written to the specified address in the PLC.

*Can be used with Mitsubishi Electric and other PLCs from various manufacturers via LAN connection. Please refer to the manual for details of compatible models.

Functions useful for system development.

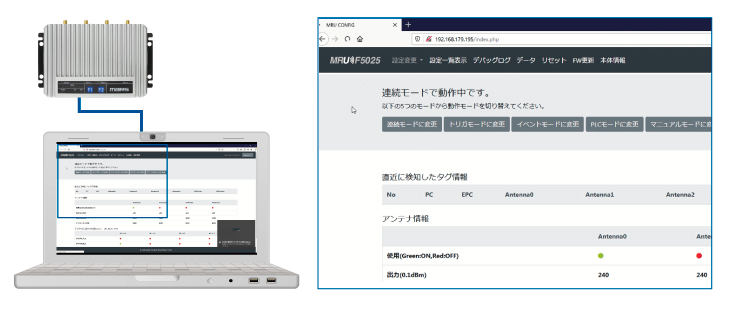

Web setting function

WEB configuration function Various settings can be configured using a web browser such as Chrome or Edge. It is also possible to import/export settings such as data destination, transmission protocol, read operation settings, digital input/output, antenna port, radio output, radio channel, own IP address, DNS and default GW.

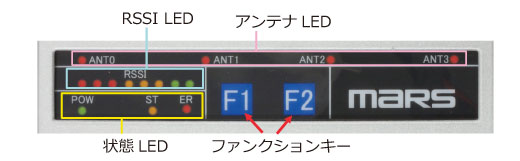

LEDs and function keys

Equipped with a status LED display and function keys with various functions. Speeds up development work.

- Antenna LED to indicate which antenna is currently being read.

- RSSI LED indicates the RSSI value of the IC tag being read (RSSI: received signal strength from the IC tag).

- Function keys: During system development and setting, the F1 key can be used instead of the sensor to test the trigger input. (in trigger mode/PLC mode).

Data storage functions useful during development and customisation.

During initial installation verification, it is often necessary to temporarily install the unit on site to see how data can be collected.

With the MRU series, data can be stored in the unit’s internal memory alone, without the need for a PC, etc., and the data files can be retrieved for verification at a later date.

Configuration file import/export

Various settings can be imported/exported as a configuration file. This makes it easy to copy settings and set up alternate machines in the event of a failure. rt/export

920MHz帯RFID 無線局の申請について

本機をご使用いただく場合、構内無線局登録局の申請が必要となります。

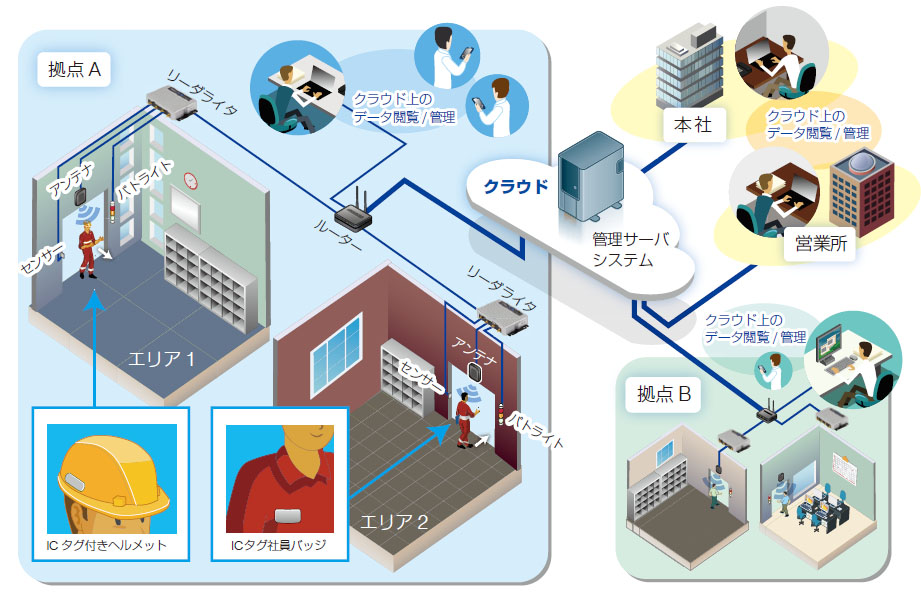

Examples of use

Hands-free passage management

Centrally manage access to and from multiple locations via the cloud

- Support for HTTPS communication

- Various settings can be made in a browser; once set up, the system works by turning on the power and sending data to the cloud in JSON format.

- The MRU/FRU series is equipped with an autonomous operation mode and can operate without a PC. Data can be transmitted to a cloud server via a router by itself. Fast and easy system construction and operation is achieved.

Product Specification

| model | MRU-F5100JP | |

|---|---|---|

| Mode of operation | [Manual mode] Operated by a command from a higher level. | |

| [Autonomous Mode] Equipped with intelligent functions for autonomous operation. | ||

| RFID | Frequency | 916.8~920.4MHz |

| UHF RFID Standard | Compliant with ISO/IEC 1800-63(6C) (EPC Global Class1 Gen2) | |

| Transmission power | 1W(30dBm) | |

| 5 to 30 dBm, variable in 0.1 dBm steps | ||

| 無線局申請 | 必要(構内無線局免許局、陸上無線局免許局) | |

| Number of antenna ports/connectors | 4-port, SMA-J | |

| Connection interface | LANポート : 10Base-T / 100Base-TX(全二重) | |

| RS-232C (for data max. 115.2 kbps) x 1 port | ||

| RS-232C (115.2 kbps for debugging) x 1 port | ||

| Digital input/output | DIO 4 points each for input and output | |

| Function key | F1 F2 | |

| Power supply rating | Input voltage | DC: 12V/24V ±10% (POWER connector) or PoE: 37.0-57.0V Alternate A/B (LAN connector) |

| Current consumption | DC:max 1A@12V/0.5A@24V PoE:IEEE802.3af Class 0 |

|

| Dust and spill resistant | IP4X | |

| Operating environment | Operating Temperature and Humidity | -20 to +55°C (non-condensing) / 20 to 85% RF (non-condensing) |

| Storage temperature and humidity | -20 to +60°C (non-condensing) / 10 to 85%RF (non-condensing) | |

| External dimensions (*excluding projections) | 175(W)×107(D)×31(H)mm | |

| weight | 740g | |

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.