How it was introduced

The company was using paper ledgers to manage its production jigs and fixtures, but the status and whereabouts of the jigs and fixtures were not known and it took time to locate them each time, so greater efficiency was required. The company wanted to use RFID to manage the whereabouts of jigs and fixtures, and we were given the opportunity to propose our one-stop service, from the selection of UHF tags to the provision of hardware, system design, installation and set-up support.

Pre-implementation issues

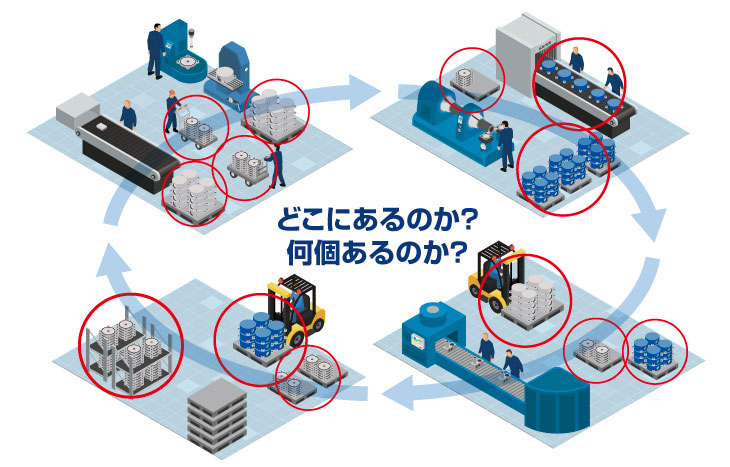

①Time consuming to locate jigs and fixtures because you do not know where they are.

A large number of fixtures are managed using a paper ledger, but location management is complicated, causing problems such as not having enough of the required number of fixtures when you need them, and having to spend time looking for them each time. We want to make stock control and location management as easy as possible.

②To avoid defects due to deterioration of fixtures

Purchase dates and maintenance histories are not readily available in the field, and it is not possible to keep good track of what and how often it has been used, preventing adequate and appropriate quality control.

③I want to know how production is going.

We want to monitor the production progress of the products being processed, together with the actual use of fixtures and pallets.

Implementation Solution

Operation flow

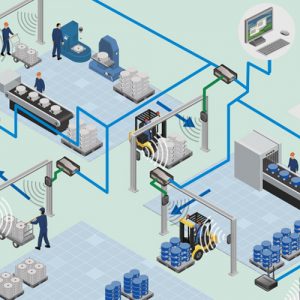

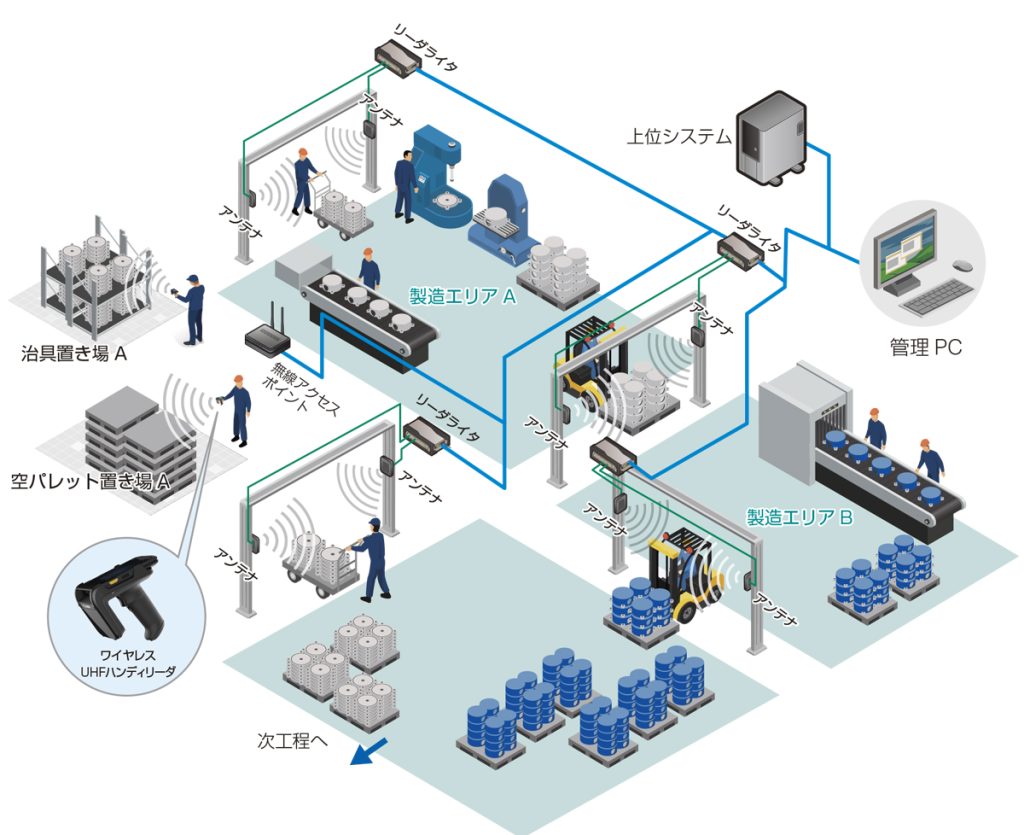

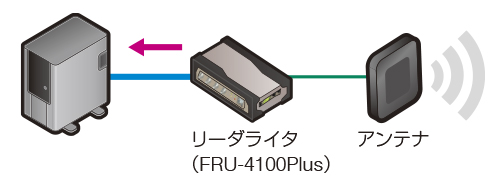

IC tags attached to production fixtures and pallets are read by fixed readers and writers (gate antennas) installed between areas to record actual results. The data recorded by the fixed reader and handheld can be viewed on a management PC.

Key points of introduction

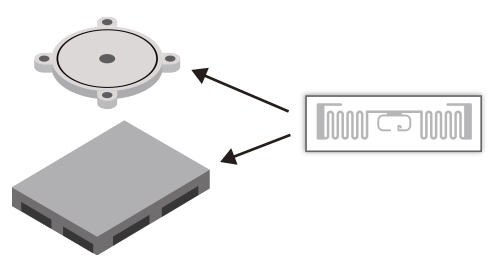

UHF IC tags on jigs and pallets

Select the most suitable tag and mounting method depending on the object.

Autonomous RFID reader/writer reduces development costs.

The FRU-4100Plus stand-alone RFID reader/writer does not require a PC for control and can automatically take a read when power is applied and send the data directly to a server on the network. As the host system does not require complex reader/writer control, system development costs could be reduced. Our specialist engineers carried out a survey, proposed the most suitable antenna and IC tags, and carried out testing – installation and installation to ensure stable operation.

Post-implementation effects

I no longer have to look for them.

We now know which fixtures and pallets are where and no longer run out of the right number when we need them.

Thorough quality control of jigs

By understanding the actual use of the equipment, it has become possible to manage appropriate maintenance times, replacements, etc. and maintain appropriate stock at appropriate cost.

Thorough quality control of fixtures.

By understanding the actual use of the equipment, it has become possible to manage appropriate maintenance times, replacements, etc. and maintain appropriate stock at appropriate cost.

Introduction flow

Many RFID installations. You can rely on us.

We have a wealth of information and expertise gained from inspecting many sites.

Based on this, we make the best suggestions for our customers and build a complete technical support system. If you have any questions, no matter how trivial, please do not hesitate to contact us.

MTS pre-introduction consultancy

Introduction flow

- Customer enquiries.

- requirements hearing

- rough estimate

- On-site survey

- Formal quotation

- Equipment and system installation

A team of specialist engineers with extensive local experience will carry out the survey and installation, giving you peace of mind.

- Choice of IC tags and hardware equipment

- System proposals

- Suggestions for site improvements