AI Appearance Inspection System Enabling a Small-Scale Start

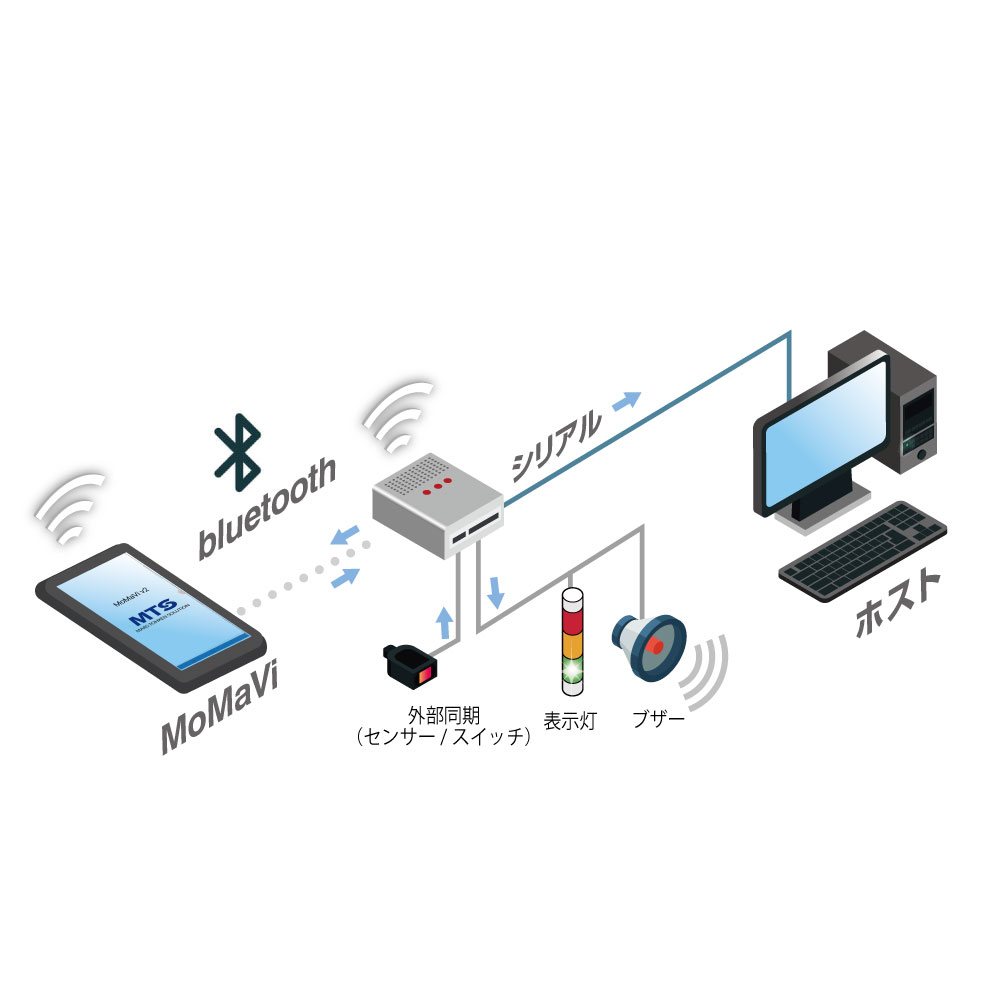

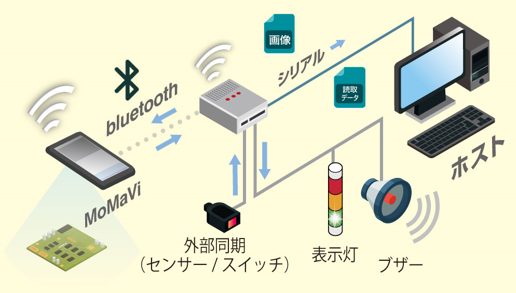

The smartphone-based system “MoMaVi” offers wide-angle inspection with minimal need for read distance adjustment, allowing for quick deployment. It can be easily integrated into systems via Wi-Fi, and through a wireless I/O box, it supports DIO integration with sensors and switches.

For more advanced applications, such as embedding into production lines, we offer the shared-application-based “Edge AI Camera VisAI-Edge” and the “VisAI-Win” system for Windows devices. By first using MoMaVi as a trial device to verify feasibility and effectiveness, users can ensure more efficient implementation when transitioning to full-scale deployment.

MoMaVi is ideal for customers who:

- Find industrial cameras, dedicated lighting, or inspection systems to be over-engineered

- Lack the budget to introduce machine vision systems for each product in high-mix manufacturing

- Want to easily test detection and recognition capabilities

Key Features

Low-Cost Proof of Concept (PoC)

Use the smartphone version as a trial device

The VisAI product family includes the industrial-grade “VisAI-Edge” and Windows-based “VisAI-Win”, both equipped with a shared application. The easy-to-try MoMaVi smartphone version allows for first-stage verification of feasibility and effectiveness, helping visualize operational changes and outcomes prior to full-scale introduction.

Subscription Plan Available

A subscription-based plan is available for easy adoption. Please contact our sales team for details.

Simple GUI for Anyone to Use

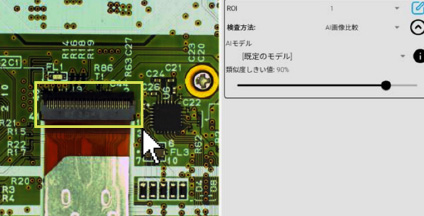

3-Step Inspection Setup

One of VisAI’s major strengths is its ease of use. No programming or deep learning expertise is required. The intuitive GUI (Graphical User Interface) has been highly praised by customers. Basic setup is completed in three simple steps:

- Capture the target with the camera and drag to set the inspection region (ROI) on screen

- Select the appropriate inspection method from a dropdown list

- Set threshold values for pass/fail or define processing logic for recognized data

Convenient Features for Enhanced Efficiency

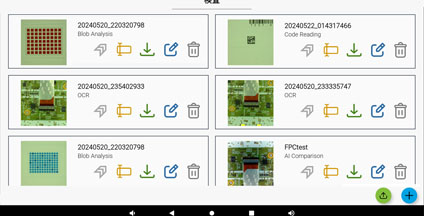

Scenario Registration Function

Multiple inspection setups can be saved as “scenarios” and recalled with a single touch when needed.

AI Model Training Tool (Optional)

Pre-installed AI models for image comparison (deep learning) are available. For more precise inspections, the “VisAI Training” tool allows users to create custom AI models. Even non-specialists can use the intuitive GUI, supporting smooth internal AI model development.

Flexible System Configuration

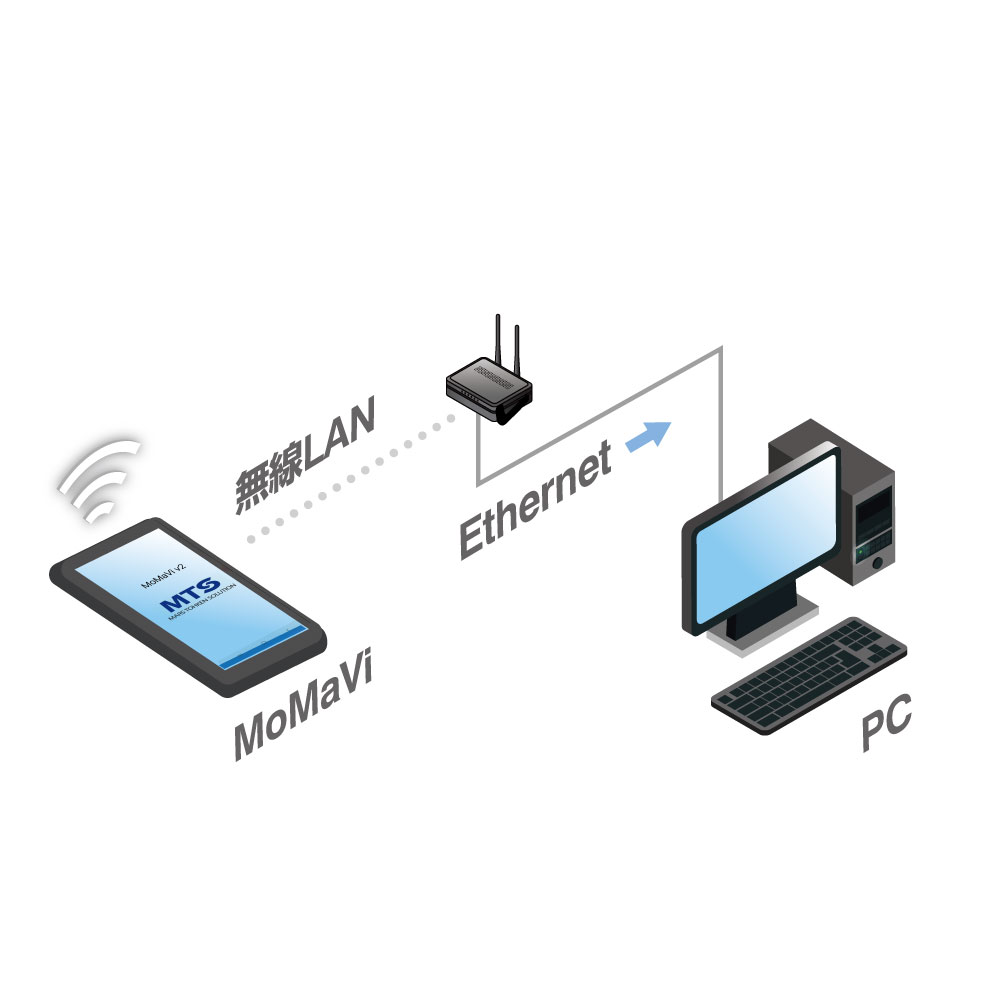

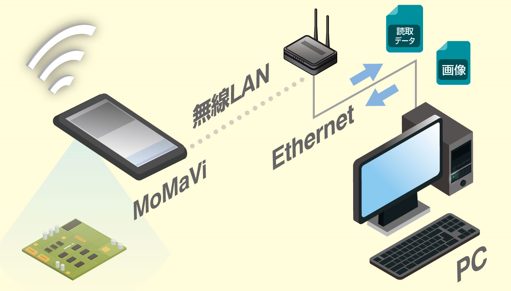

Wi-Fi connection

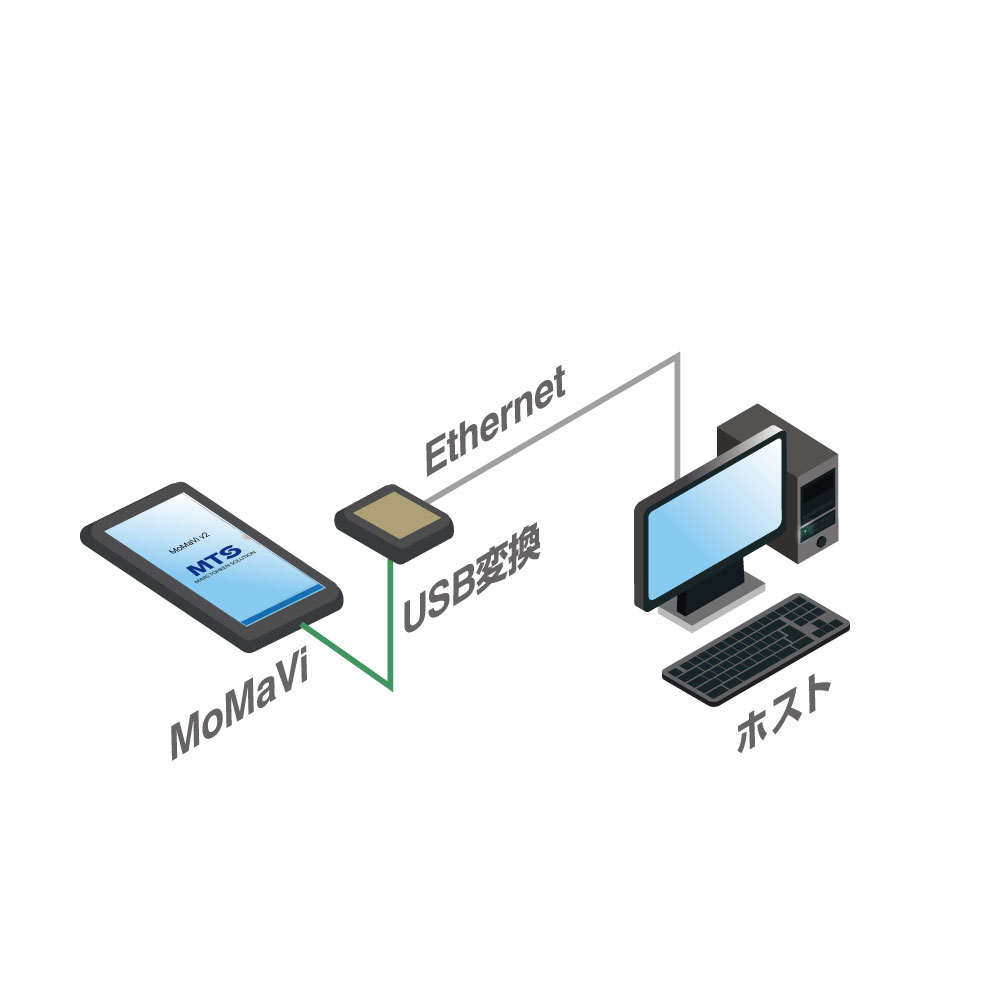

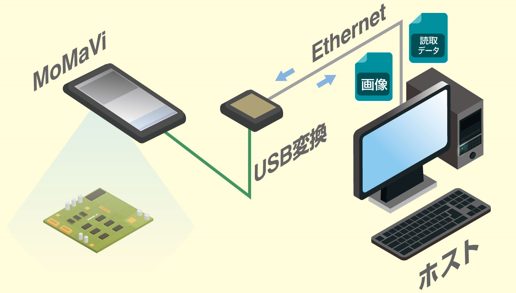

USB connection

DIO integration

What MoMaVi Can Do

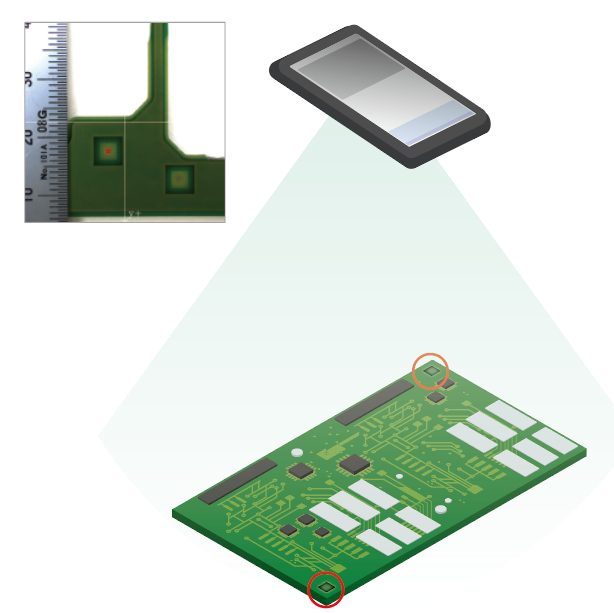

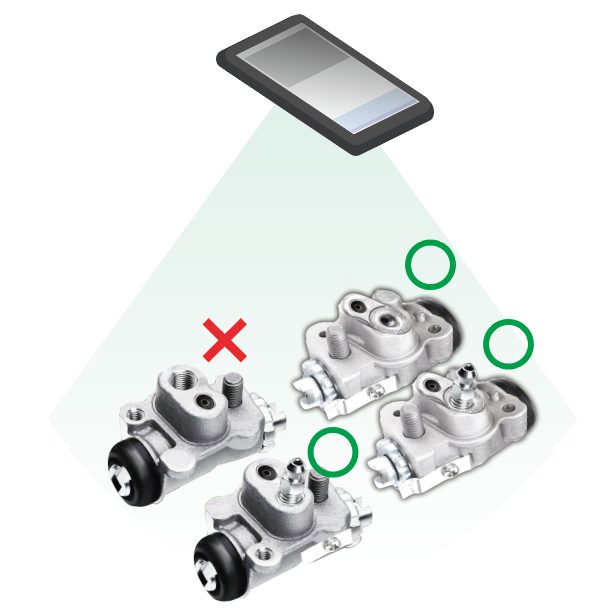

Shape Inspection of Products and Parts

Use Case: Verifying completeness of parts before shipping

Detects whether parts are properly attached or assembled, and distinguishes between acceptable and defective items.

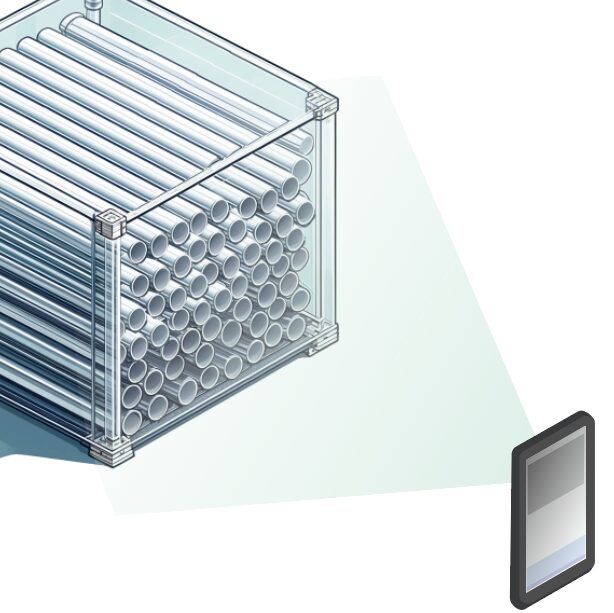

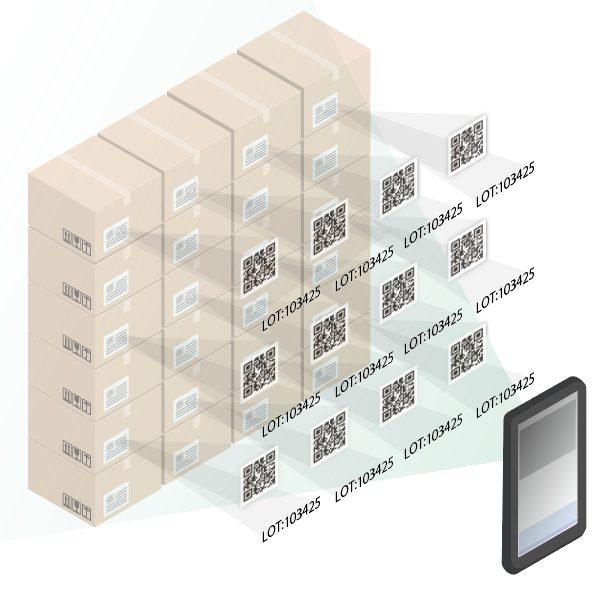

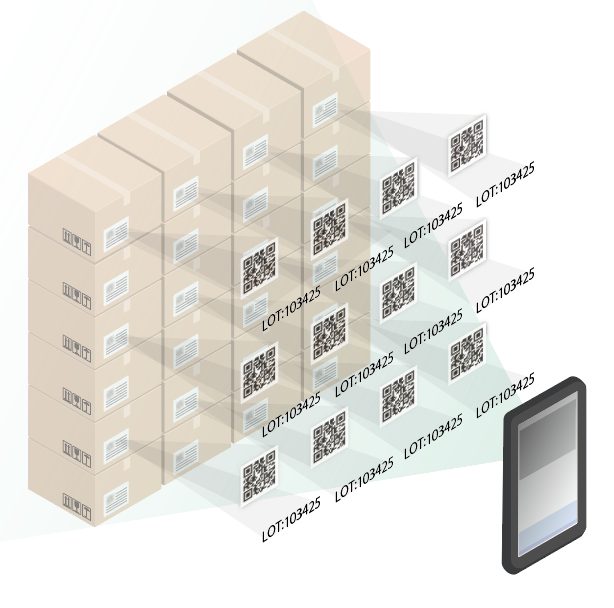

Symbol Reading (Bulk Reading Supported)

Symbol Reading (Bulk Reading Supported)

Reads and verifies multiple barcodes printed, labeled, or engraved on products or parts. Wide-angle imaging via smartphone enables high coverage.

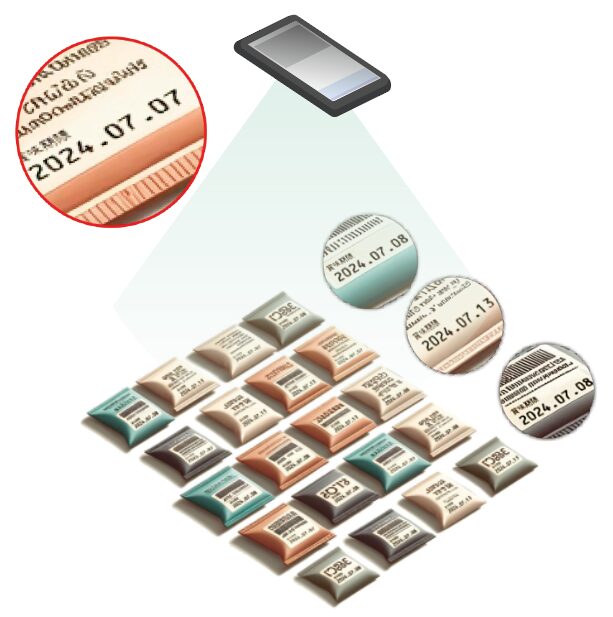

OCR (Optical Character Recognition, Bulk Reading Supported)

Use Case: OCR with selective text extraction

Can read multiple strings of text at once. Automatically and quickly extracts necessary character data from designated areas.

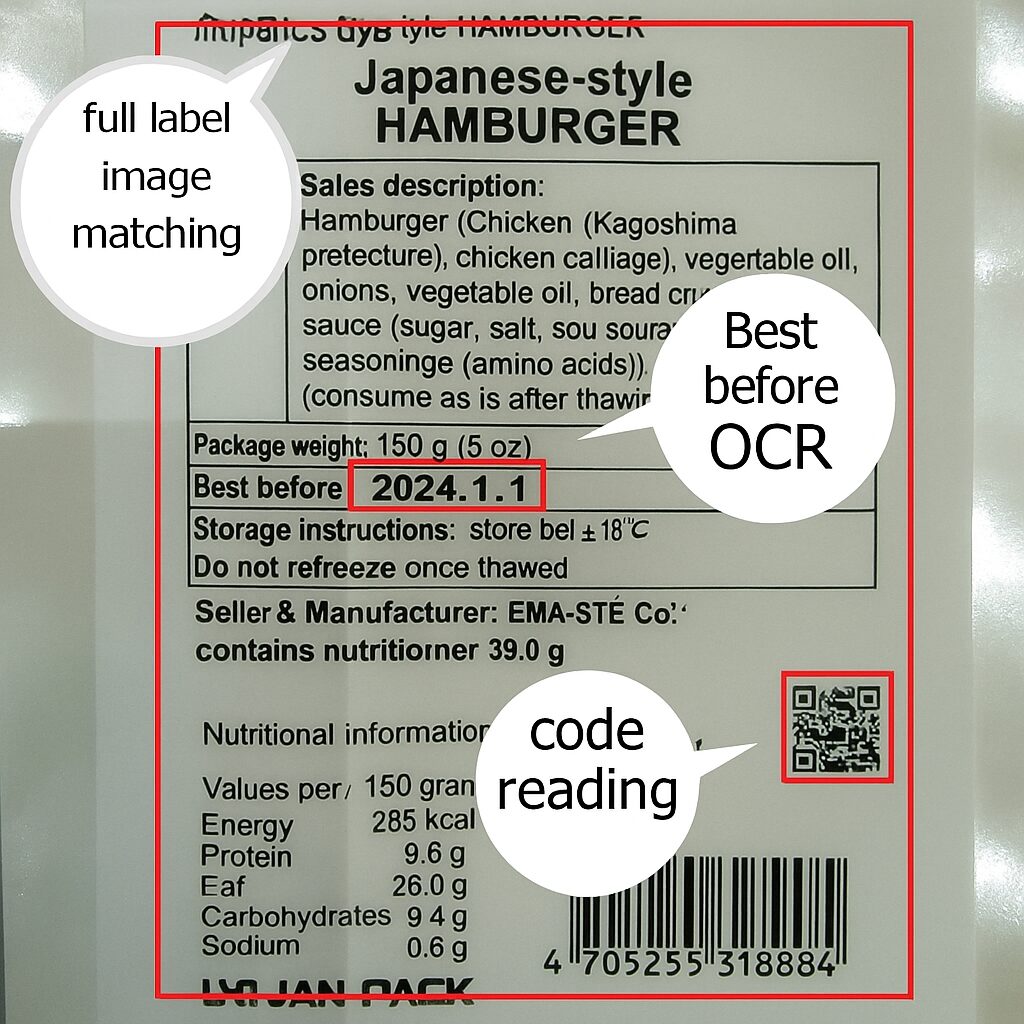

Combined Image/OCR/Barcode Inspection

Use Case: Integrated image/OCR/barcode verification

Combines OCR and barcode reading with pattern matching for comprehensive inspection.

Frequently Asked Questions (FAQ)

Here are answers to commonly asked questions about MoMaVi, presented in a Q&A format.

We recommend Android 10 or later, with a Snapdragon 700 series or higher SoC and at least 6 GB of RAM.

Devices with wide-angle lenses can capture A3-sized images without needing distance adjustment.

If you have a specific device you’d like to use, we can accept it for verification and provide feedback or suggestions after testing.

MoMaVi can be connected wirelessly via Wi-Fi or through a wireless I/O box, enabling DIO integration with sensors and signal lights.

Wired connection is also possible via USB-OTG.

Yes. We offer rental packages that include the MoMaVi device, tripod, and charger for 1 week to 1 month.

Upon full deployment, your settings can be fully transferred to VisAI-Edge or VisAI-Win platforms.

Yes. All inspections are processed locally on the device.

Even in offline environments, MoMaVi functions normally. Results can be transmitted in batch mode or exported as CSV files for later transfer.

MoMaVi excels in:

- Quantity counting

- Color/shape sequence checks

- Presence/absence detection

- Bulk QR code reading

- Bulk OCR

- Combined barcode + OCR inspections

- Its wide-angle smartphone camera enables full capture of even large workpieces.

MoMaVi performs well under standard indoor fluorescent lighting.

For challenging conditions such as backlighting or low brightness, ring lights or LED panels can be added to enhance image clarity.

In continuous inspection mode, it lasts about 5 hours

(e.g., Snapdragon 778G device, 60% screen brightness, Wi-Fi ON).

It also supports external power supply via mobile battery.

Yes. It is compatible with general EMM/MDM systems.

You can also lock the device into a dedicated kiosk mode to restrict use to the inspection app only.

Yes. You can store up to 200 inspection scenarios using the scenario registration function.

Linked inspection settings can be recalled simply by scanning a QR code.

Yes. We have implemented real-time result transmission to smart glasses via Wi-Fi.

Custom UI development is available to optimize the experience for smart glass users.

For enquiries about this product or to discuss its implementation, please click here.

Implementation process (items and procedures to be checked on site).

The following checklist may be useful to facilitate the induction study.

*For inspection items, it may not be possible to deal with minute details that cannot be visually identified or described.

Inspection method

- Presence check

- colour check

- Sequence check

- Quantity Count

- Pattern Recognition

- Shape/orientation inspection

Subject identification

This item is used to determine the size and material to be inspected and to specify the required specifications and configuration.

For example, it is necessary to check what inspections are currently being carried out.

- Inspection area (range)

- Inspection object size

- Material (metal/resin/paper)

- State (fixed/mobile)

- Inspection criteria (OK/NG)

Environmental controls

The environment and conditions at the time of the inspection are determined and the content of the system is specified.

Example: Inspection load from one direction only|Inspection from multiple directions possible|Personnel can provide assistance such as aligning the direction of the object.

Conditions such as those listed above should be checked.

Communication System

- Cable LAN

- Wireless LAN

- USB

- RS-232C

Reading distance

Camera and subject positioning

Devices to communicate with

Read verification

Workpiece loan

- OK

- NG

field test

- OK

- NG

Other.

Current/past situation.

Data processing method

The results of the readings need to be checked for data processing methods such as [I want to save (NG only/all) images], [I want to save text strings], [I need to judge OK/NG only], [I want to return a specific command at a higher level].