Barcodes and 2D codes

We are not just a manufacturer of barcode scanners, but have a proven track record of providing direct consultancy to solve our customers’ problems, with the aim of providing the best tailored solutions to meet their requirements.

Strengths of MTS technology.

Support risk management by tracking production history

As a systems manufacturer able to propose comprehensive risk management measures for companies in the manufacturing industry, the company provides production history tracking and management systems that centrally manage the flow of goods and information.

Streamline the management of goods at logistics sites.

The company has experience in coordinating hardware such as touch-screen forklift on-board terminals and long-range readers, as well as building warehouse and inventory management systems and container management systems.

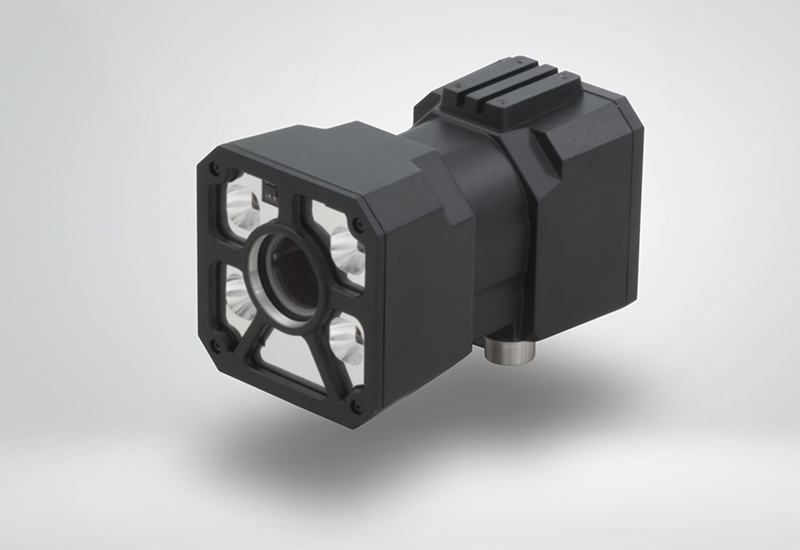

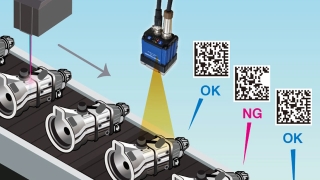

2D code scanner with image processing capabilities

Enables recognition of expiry dates, batch numbers and production symbols, as well as inline barcode print quality determination. Contributes significantly to line efficiency.

Direct marking compatible equipment

Print 2D codes directly onto metal and precision parts. Enables printing on small parts where space is at a premium, or on empty spaces after assembly. It is also used by companies in the automotive industry due to its excellent durability.

Provides equipment for a wide range of environments

The product range includes bar code scanners that can be used safely in areas where static electricity is not permitted, handy 2D code scanners with explosion proof construction ideal for working in hazardous areas, and other products that can be used in special environments.

Use of new codes in the medical and pharmaceutical fields

Compatible with the new barcode (GS1 composite symbol) introduced in the medical and pharmaceutical sector in autumn 2009. Contributes to the safety and security of the medical field by providing a verifier that verifies accurate information both in-line and off-line.

Application and implementation examples

PLC link-compatible 2D code readers & RFID readers with no communication programme required

Is it difficult to understand the scanner commands and program the PLC?If you are using one of our PLC Link enabled scanners… you can set the scanner to the barcode data write memory address in the PLC and it will automatically write the read barcode data to the specified memory. Memory monitoring logic is all that is required. Of course, the read/write data is also handshaked with the PLC memory.Our industrial barcode/2D code scanner products come with PLC connectivity as standard.※Please contact our sales team for compatible models.

Highly reliable antistatic scanners that can be used with confidence in locations where ESD (electrostatic discharge) measures are required.

With the increasing density and integration of electronic devices, the control of electrostatic charge levels in the manufacturing process has become an important issue.In addition, many electronic devices, such as those used in automobiles, are used everywhere in our daily lives.Considering the damage that can be caused by the failure of electronic devices due to static electricity, ESD measures are now a must.

Infection Prevention Measures Sterilisation and Disinfection Compliant Barcode Scanners

Many have been used in medical practice in the USA. How does it differ from the usual antimicrobial model?Due to the spread of the new coronavirus infection, companies using barcode scanners are now using alcohol and disinfectant wipes as a measure to prevent infection. This is particularly important in locations where scanners are shared by several people.Conventional scanners have a high risk of damage to the housing and defects due to repeated wiping and disinfection, and there is a growing demand for barcode scanners that can withstand alcohol and strong disinfectants.