Ideal for customers facing such on-site challenges.

①I want to smoothly give production instructions

We have been managing our product production using paper ledger, which has led to issues such as easily dirty or unreadable barcode and text prints. In addition, there has been a demand to reduce printing costs and installation time of paper, and we were looking for a system that can automatically identify without much manual effort.

②Eliminating production instruction mistakes and improving efficiency.

In the painting process, it was necessary to remove and attach the production instruction sheet each time before and after painting, and it took a lot of time to check for mistakes to prevent incorrect attachment.

③I want to grasp the production status.

I would like to know the progress status of the products being processed in addition to the production results of the products.

Introduced solution

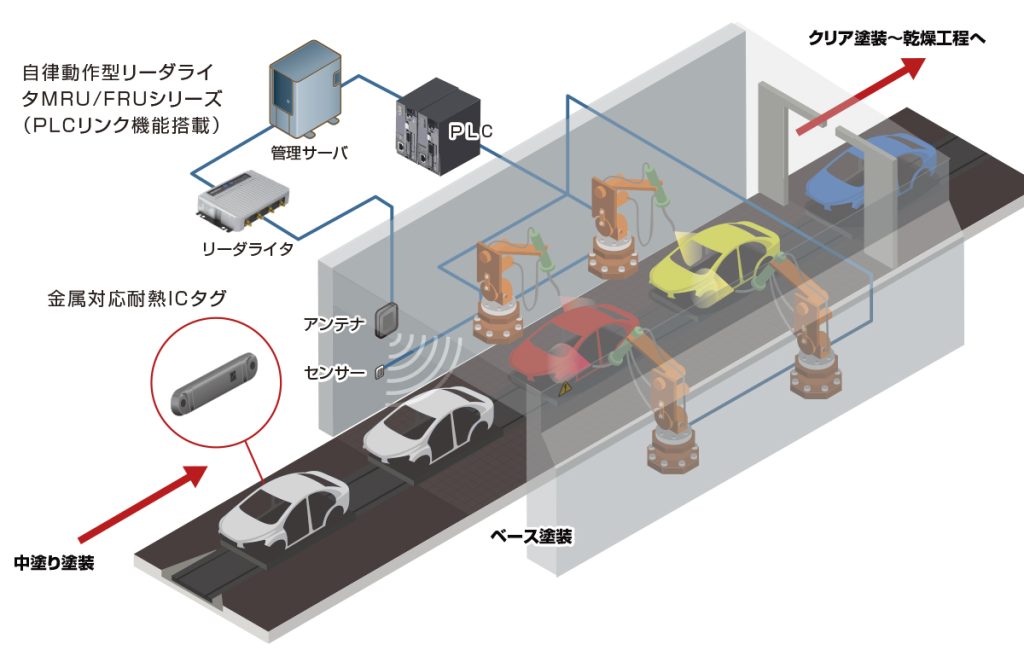

System example

●PLC link function

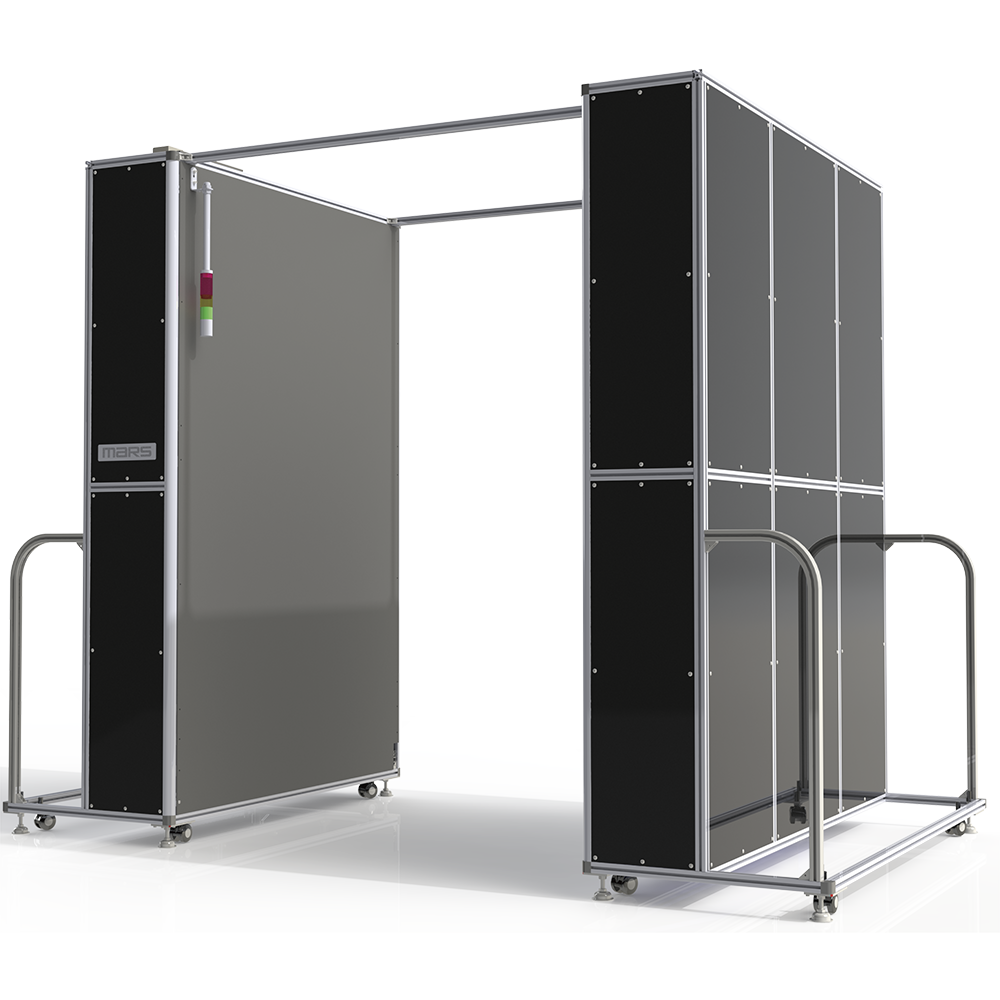

By using the PLC link function built into the autonomous reader-writer MRU/FRU series, reading data can be directly written to the PLC data memory. RFID is built into the production system, and the information on the IC tag is read to send each painting instruction to the robot. This system supports small-lot production of a wide variety of products.

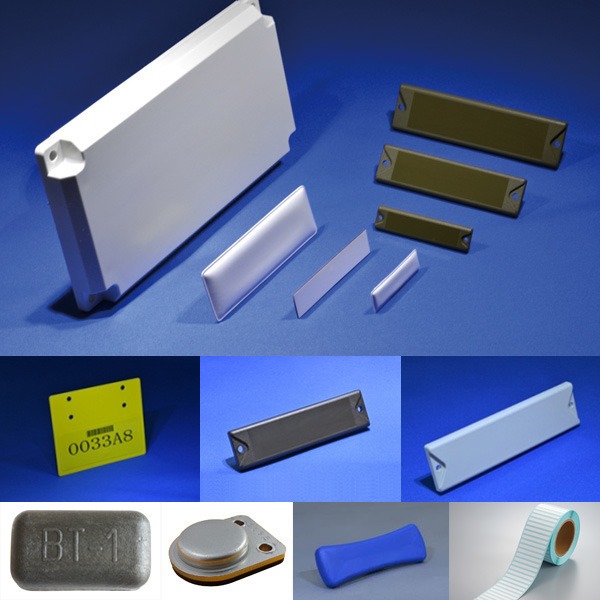

●Metal-compatible heat-resistant IC tags

It can be installed on the jigs that transport the vehicle throughout the entire production line. Tags that can withstand temperatures up to 200℃ were selected because resistance to the high-temperature drying process carried out at high temperatures is required.

Advantages of implementation

By utilizing data from UHF tags, production instructions have become unnecessary for some processes.

By linking the information on production instruction documents with UHF tag data, work instruction documents were eliminated in some processes, leading to a reduction in paper costs. Moreover, this helped to improve productivity by avoiding issues with readability or legibility that often occur when paper is used.

By attaching UHF tags to the transport fixtures, the work of removing work instructions has been eliminated.

Previously, in the painting process, the production instructions were removed each time. However, by using UHF tags that are resistant to dirt and high temperatures, the need to remove them has been eliminated. As a result, the risk of attaching the wrong production instructions has been eliminated, and the workload of verification has been significantly reduced.

I can understand the production status.

By integrating and collecting information from UHF tags in all manufacturing processes including the painting process, it has become possible to monitor the production status in real time.

Introduction flow

Many RFID installations. You can rely on us.

We have a wealth of information and expertise gained from inspecting many sites.

Based on this, we make the best suggestions for our customers and build a complete technical support system. If you have any questions, no matter how trivial, please do not hesitate to contact us.

MTS pre-introduction consultancy

Introduction flow

- Customer enquiries.

- requirements hearing

- rough estimate

- On-site survey

- Formal quotation

- Equipment and system installation

A team of specialist engineers with extensive local experience will carry out the survey and installation, giving you peace of mind.

- Choice of IC tags and hardware equipment

- System proposals

- Suggestions for site improvements