How it was introduced

In an attempt to improve labour efficiency, the company’s factory was faced with the problem of not being able to monitor the operating status of forklifts and the need to get on and off the forks during order picking. The company also wanted to avoid incorrect deliveries and delays caused by human error. Our company, which can provide a one-stop service from hardware supply and system design to installation and set-up support, was given the opportunity to propose operational improvements using RFID technology and our experience in the logistics field.

Pre-implementation issues

①High burden of picking time for forklift operators.

Because the picking operations were carried out using a handheld terminal, it was necessary to get off the forklift each time the order was picked. In addition, the small screen of the handheld terminal made it difficult to use, and it took time to recharge the battery and manage the equipment each time.

②Inability to monitor operational status and ineffectiveness of instructions.

It was difficult to issue instructions efficiently from the office because the status of forklift movements to the shipping point could not be monitored in real time.

③Burden of inventory work

Inventory was time-consuming because barcodes had to be scanned one at a time.

Implementation Solution

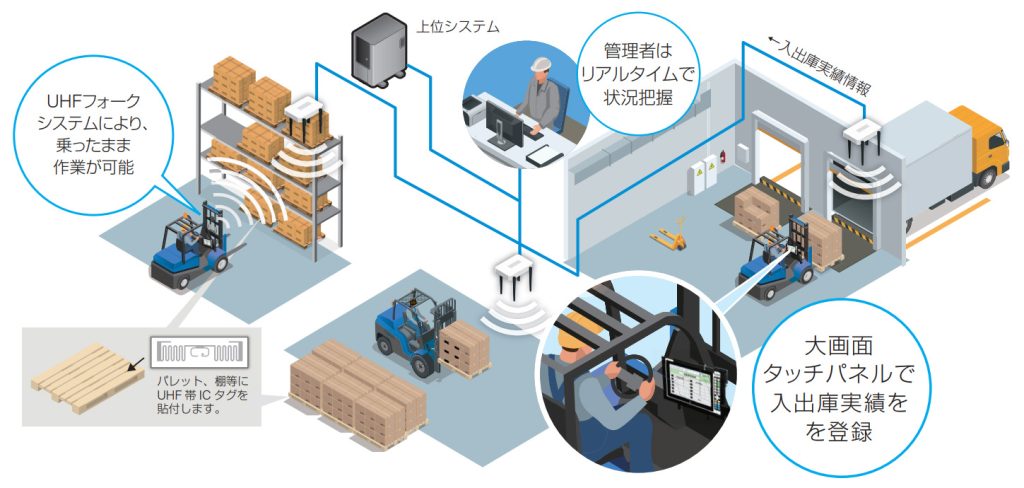

Operation flow

UHF Forkは、UHFタグを自動で読み取ることで区画番号と位置を結びつけ、効率的な管理を可能にします。これにより、現場での作業負担を軽減し、位置管理の精度を向上させることができます。

Managers can monitor the situation in real time

Large touch panel for registering records of incoming and outgoing shipments

Enabling work without getting off the forklift

UHF forks use RFID to automate the reading and registration of cargo and location information. Forkmen automatically acquire cargo information for inbound, outbound and picking without dismounting.

Post-introduction effects

Streamline picking operations for forklift operators.

This allows the operator to check picking information on the on-board terminal and work without leaving the truck. This also prevents pallets from being picked incorrectly.

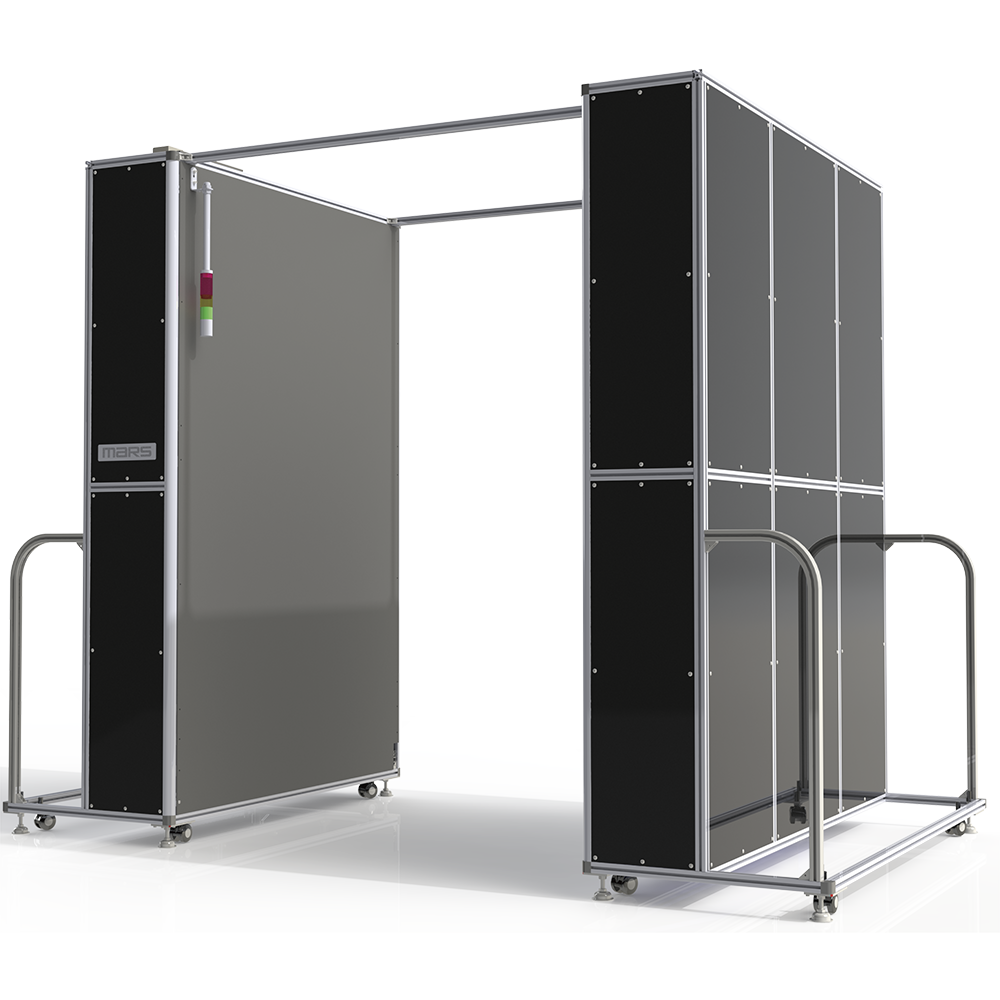

UHF gates to capture movement information

By reading the information on IC tags attached to pallets at the UHF gate, shipment status can be monitored in real time. This enables managers to monitor the status of shipments and manage deliveries efficiently.

Simplify the inventory process

UHF tags can be attached to pallets and linked to each product to enable batch inventory using RFID readers.

Introduction flow

Many RFID installations. You can rely on us.

We have a wealth of information and expertise gained from inspecting many sites.

Based on this, we make the best suggestions for our customers and build a complete technical support system. If you have any questions, no matter how trivial, please do not hesitate to contact us.

MTS pre-introduction consultancy

Introduction flow

- Customer enquiries.

- requirements hearing

- rough estimate

- On-site survey

- Formal quotation

- Equipment and system installation

A team of specialist engineers with extensive local experience will carry out the survey and installation, giving you peace of mind.

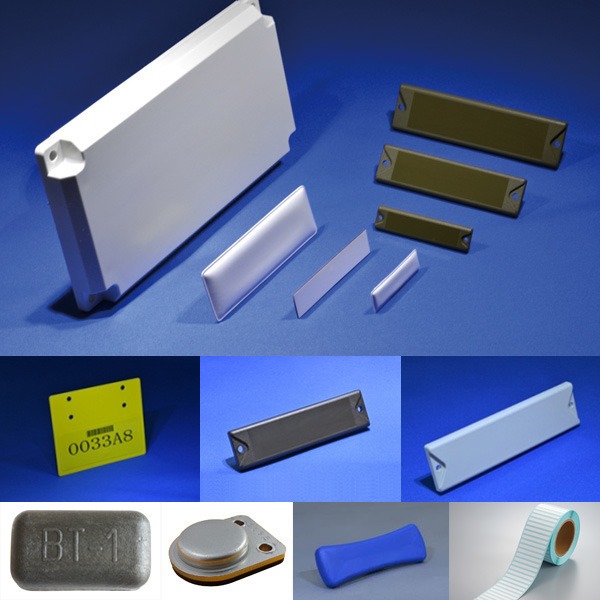

- Choice of IC tags and hardware equipment

- System proposals

- Suggestions for site improvements