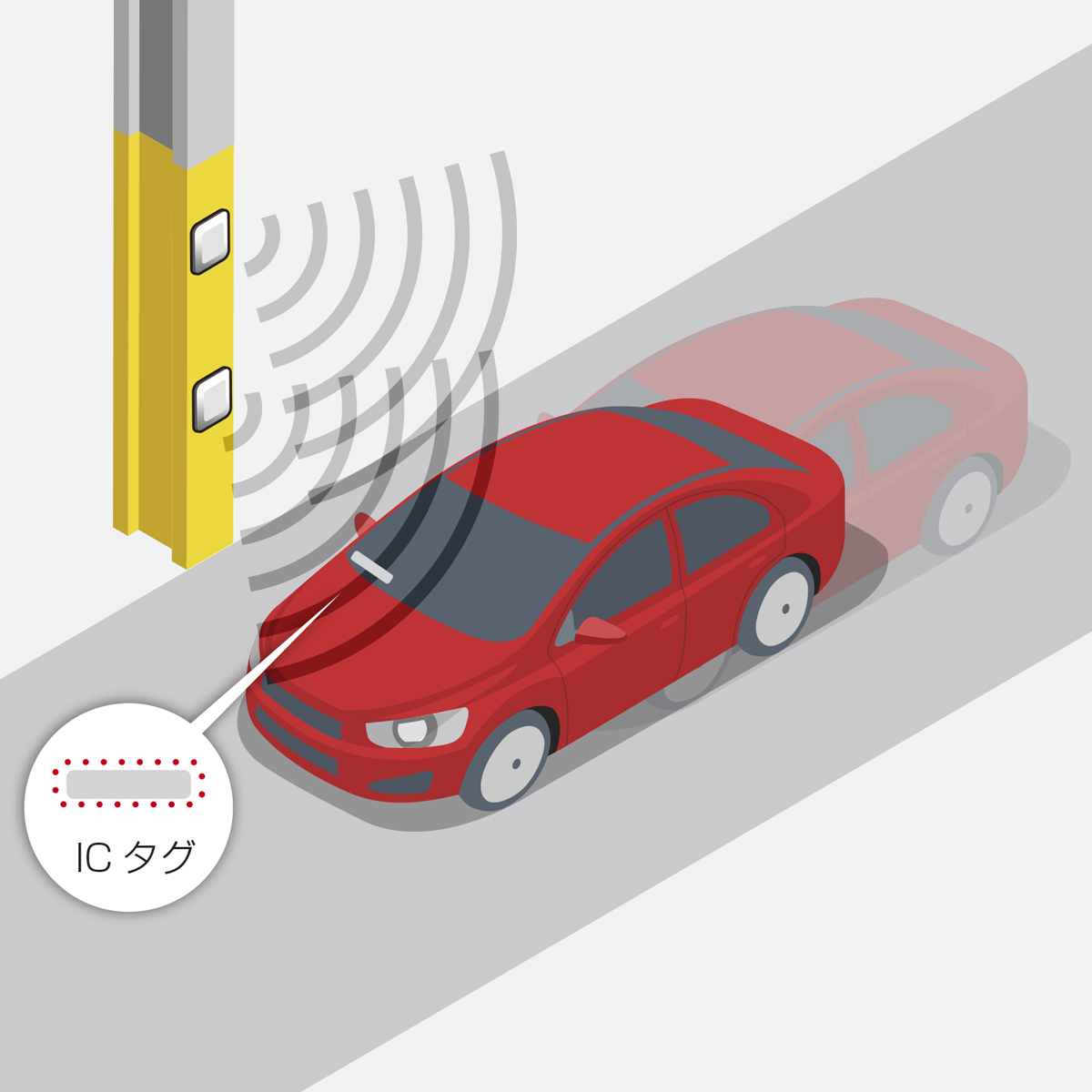

Utilization of RFID in the FA industry: Painting Process (for a certain manufacturing company)

The use of UHF technology enabled easy individual management during the painting process, resulting in a reduction in human error and a shortened total operation time, leading to improved work efficiency. (Client from a certain manufacturing industry)At this factory, we managed each process by attaching a paper ledger (work instruction sheet) to the product, but problems such as illegible due to paper stains or incorrect attachment occurred, leading to a decrease in production efficiency. To prevent mistakes and improve production efficiency, we proposed the use of RFID technology, and our company provided one-stop support from selecting the UHF tag, providing hardware equipment, system development, to installation adjustment response.

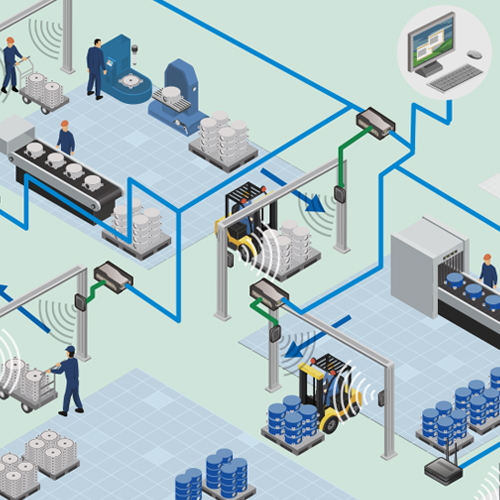

RFID Examples of use

Machinery, industrial trucks and heavy electrical equipment