RFID

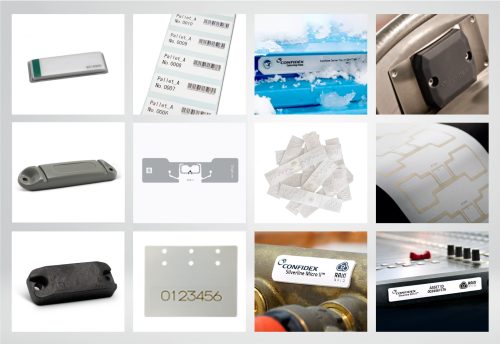

RFID (Radio Frequency Identification) is an authentication technology based on wireless communication that identifies and manages people and objects by storing data on an IC chip and communicating with a reader using radio or electromagnetic waves. An RFID system requires a reader, an antenna and an IC tag to operate.

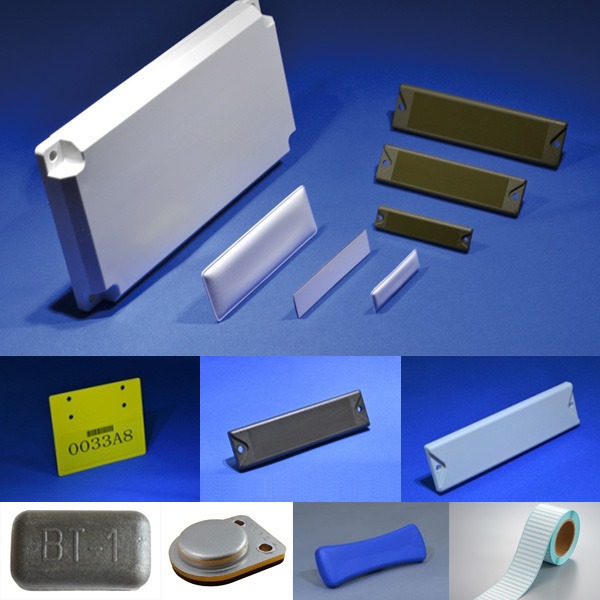

MTS RFID solutions.

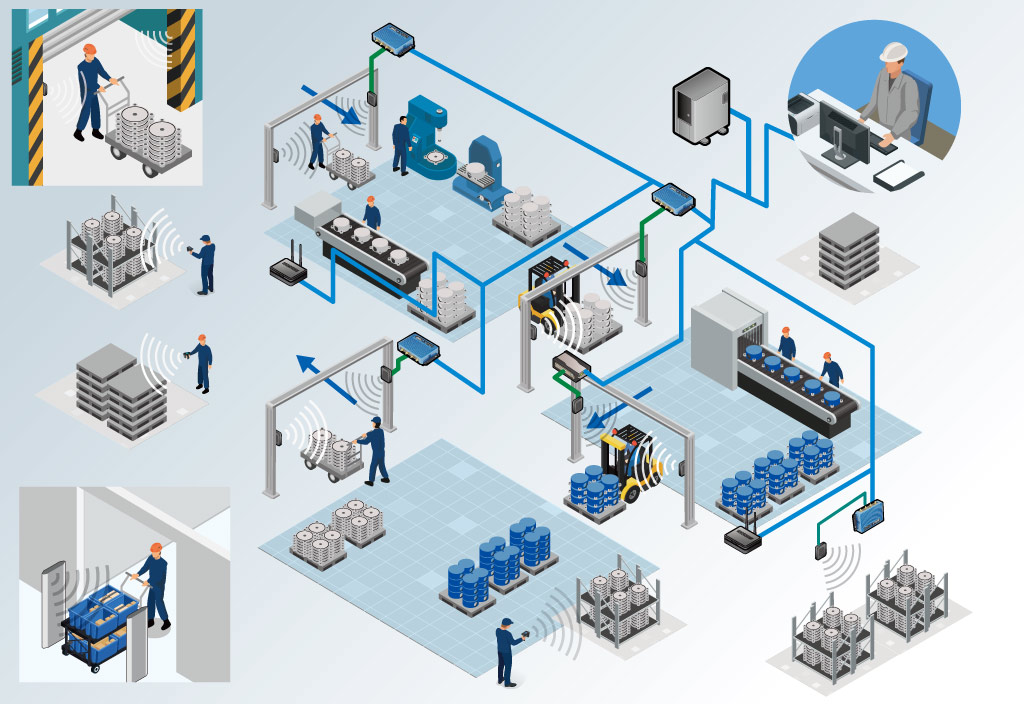

Streamline factory production lines

UHF IC tags can be used for data collection and traceability, such as when and where work-in-process flows in product assembly processes and inter-process transfers on AGVs.

NFC Employee ID Solutions

The product range includes WM Station, a time and attendance system for the logistics and manufacturing industries. The system uses employee ID cards to manage entry, exit, borrowing, etc., to streamline business management processes.

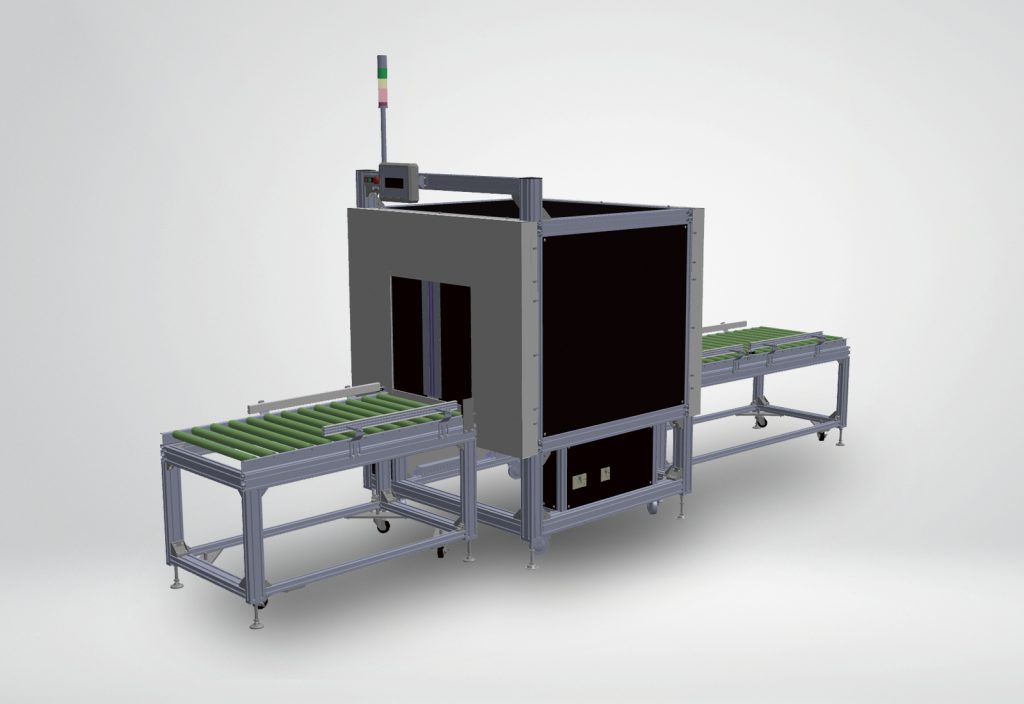

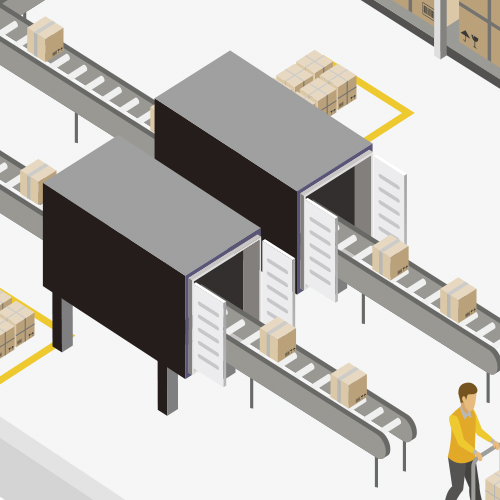

UHF RFID Conveyor

In the supply chain for apparel and other products, UHF IC tags enable batch reading in the package, significantly reducing the workload for incoming and outgoing goods inspection. The batch reading system, which achieves a high reading rate, has been well received by the companies that have implemented it.

Application and implementation examples

UHF RFID used in apparel industry for faster goods inspection/inventory.

UHF RFID tags are attached to each product, enabling batch reading via tunnel gates and automating incoming and outgoing goods inspection at the distribution centre. (A manufacturer and retailer)

Forklift operation management using UHF RFID

UHF RFID improves the efficiency of forklift operations and reduces forklift operator workload.

Construction site access control using UHF RFID.

UHF RFID has enabled management of ‘who moved where and when’ by capturing information on the movement of workers. (A construction company)