Features/Functions.

Vari-focal (variable focus) system. Equipped with autofocus and zoom functions.

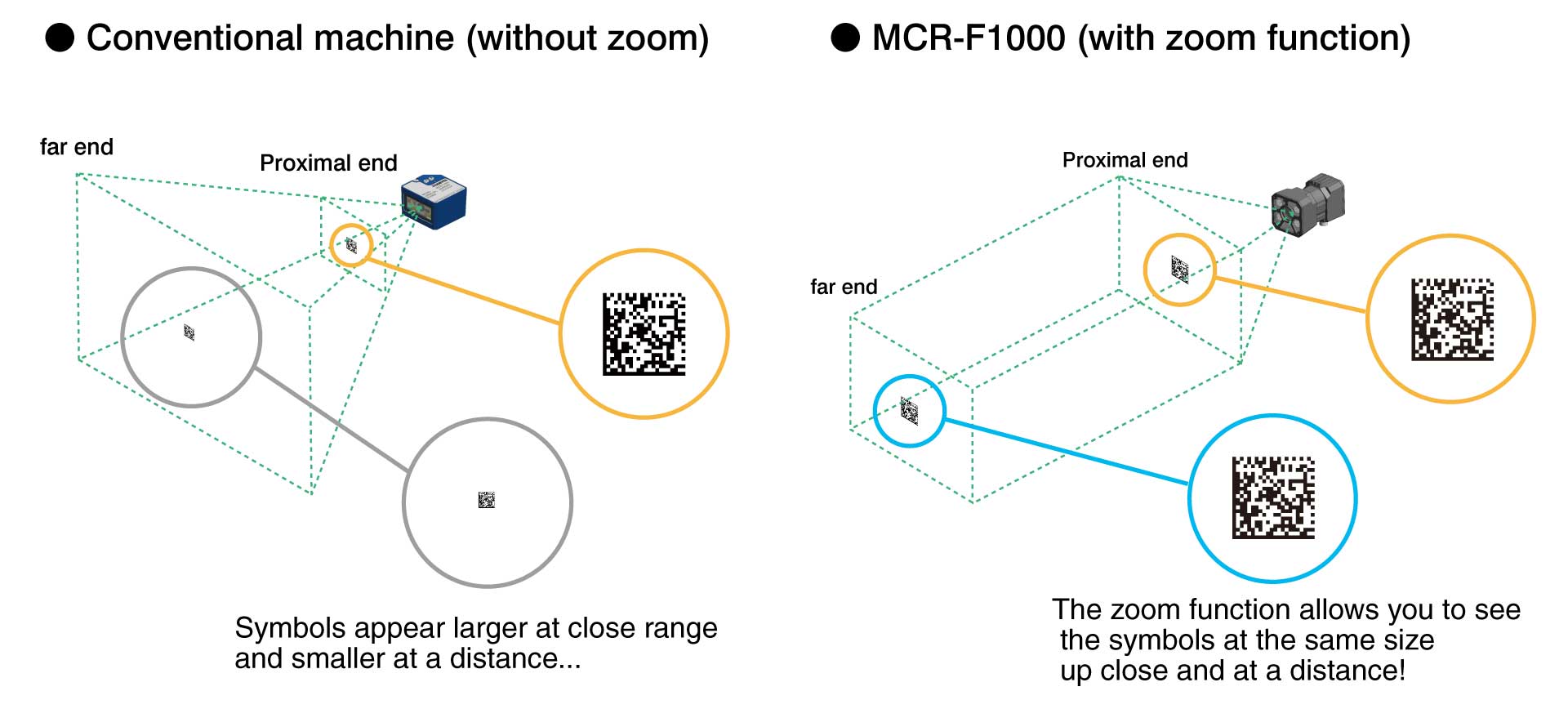

It is the first industrial code reader to use a varifocal (variable focus) system with autofocus and a 3x zoom function. The autofocus system has a deep depth of field so that workpieces of varying heights can be reliably read without the need for fine focus adjustment. Where previously the image size decreased with distance, resulting in insufficient pixels to read, the varifocal system can zoom to the same size at a greater distance.

5M-pixel global shutter CMOS image sensor for high-resolution measurements

The high-resolution 5M-pixel global shutter CMOS enables fast and accurate reading of symbols that were previously difficult to read.

Set-up support functions that do not confuse even first-time users

Configuration software (MCVConfig) with a configuration flow function that allows even first-time users to set up the system without hesitation, and various support functions for efficient and optimal settings.

Wi-Fi enabled smartphones and tablets for easy setup and maintenance

The MCR-F1000 is equipped with a wireless LAN that allows automatic adjustments to the reader and reading/writing of configuration files from a Wi-Fi enabled Android device with a dedicated app installed.

Post-installation maintenance, which used to be cumbersome and difficult, can now be performed via the wireless LAN rather than via the reader’s Ethernet cable, allowing for smooth post-installation maintenance operations.

Print quality of symbols is checked and PDF output with report function.

Inline print quality checks are available for 2D codes imaged with this product, and the print quality can be checked using the evaluation parameters of ISO/IEC 15415 or ISO/IEC TR 29158, so that the progression of the symbol over time can be seen in detail.

The trends of changes in symbols over time can be identified in detail.

※This function outputs evaluation results in the same format as the standard evaluation parameters, but is intended for performing simple checks and cannot be used as a formal 2D code verifier.

Set-up function for quick response to set-up changes.

The set-up function allows different settings to be stored for quick changes at the factory. No need to wait.

A function (Trapezoidal Correction) is provided to correct image distortion caused by reading the image at an angle.

In some cases, the machine must be mounted at an angle to the symbol, but a function to correct image distortion (trapezoidal correction function) is provided to improve readability. The trapezoid correction function can also be used for print verification, allowing accurate print verification of symbols even when mounted at an angle.

Powerful, fast processing engine with quad-core CPU.

Cycle buffer function (MAXIMG)

The cycle buffer function (MAXIMG) enables high-speed, continuous image capture and decoding with simultaneous storage in image memory. The system can read symbols even while they are moving, without detailed timing adjustment.

Dust and waterproof protection (IP67)

It is dust and waterproof (IP67) and can be used in harsh environments.

Equipped with Ethernet interface

It has an Ethernet interface and can be easily connected to the Ethernet port of a Windows computer.

Ideal for reading direct markings from laser markers and dot pens

【Image pre-processing function】

This function pre-processes the captured image to improve image quality. This function can be used to improve the reading performance of symbols with poor image quality.

【Table mode】

Up to 16 types of reading parameters can be registered, allowing the reading to be adjusted one at a time.

【Lighting unit】

The optimum illumination pattern can be set according to the reading target and conditions.

PLC link function for PLC programmer connection

The PLC is connected to a PLC, often used in factory automation, by setting the barcode data write memory address in the PLC to the code reader, which automatically writes the read barcode data to the specified memory. Of course, the read/write data is also handshaked using the PLC memory.

Introduction video

Product Specification

| model | MCR-F1000 | |

|---|---|---|

| Supported Symbols | 1D code | Code39, Code128 / GS1-128(EAN128), Codabar(NW7) ITF(Interleaved 2 of 5) , UPC / EAN(JAN) GS1 DataBar, Code93 |

| 2D code | Data Matrix(ECC200) , CompositeCode, QR Code / Micro QR Code, PDF417 / MicroPDF417, AztecCode | |

| Reading angle | PITCH: ±35° SKEW: ±35° TILT: 360° | |

| Min. resolution | 0.1mm | |

| Photosensor | Image Sensor | 2/3-inch CMOS monochrome image sensor |

| Number of effective pixels | 2448 (X) × 2048 (Y)(Approximately 5 million pixels) | |

| Focusing (Adjustment) | Auto (focus position can be adjusted automatically during installation and tuning) | |

| Scaling (of a sound wave) | Semi-automatic (manual setting of cell size and number of pixels or shooting range only). | |

| luminous part | Lighting | High intensity white LED |

| distance measurement sensor | Infrared Laser 940nm | |

| Power supply rating | Supply voltage | DC 24 V±10% |

| Current consumption | 1 A | |

| Digital input | Photocoupler isolation x 2 points Input resistance: 2.2 kΩ ON voltage: 10.8 to 28 V OFF voltage: 0 to 0.8 V | |

| Digital output | Photocoupler isolation x 3 points Max. rating DC 30 V 50 mA | |

| Buzzer | Electromagnetic buzzer | |

| Interface | Ethernet(1000BASE-T、100BASE-TX、10BASE-Te) | |

| environmental friendliness | Operating temperature | 0 ~ 40 ℃ |

| Operating humidity | 35 – 85%RH (no condensation) | |

| Storage temperature | -20 ~ 60 ℃ | |

| Storage humidity | 35 – 85%RH (no condensation) | |

| Vibration resistant | 10~150Hz Amplitude 0.15mm (full width)/X, Y, Z each direction 2 hours (※1) | |

| protective structure | IP67 | |

| Ambient illuminance | 10000 lx max. | |

| Outer dimensions | 65(H)mm × 65(W)mm × 110(D)mm (projections not included) | |

| weight | Approx. 400g (without cable) | |

※1 Test values, not guaranteed values.

※Product specifications are subject to change without notice.

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.