For enquiries about this product or service, or to discuss or consider its implementation, please contact us here.

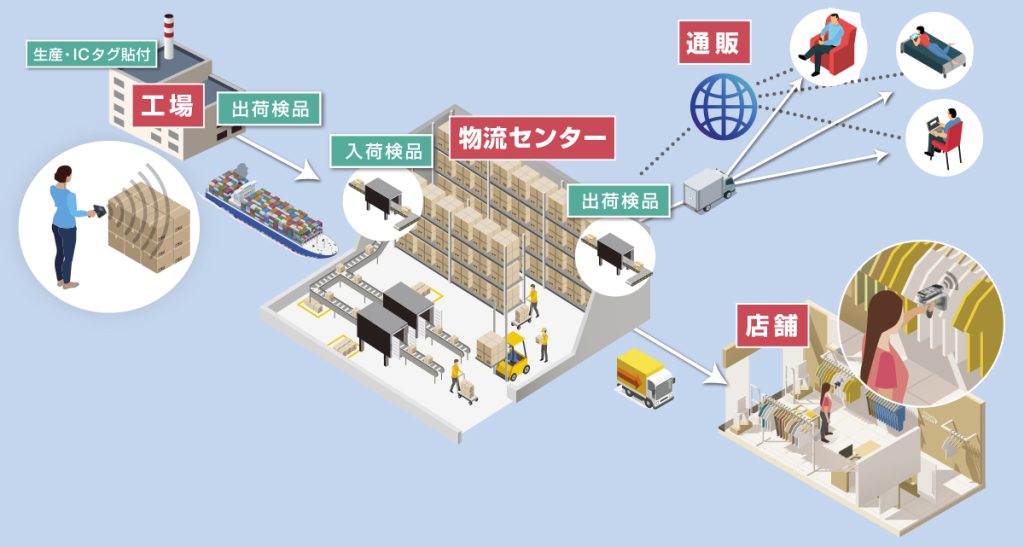

The company's distribution centre had been using barcodes to inspect incoming and outgoing goods, but as the number of items handled increased and the volume of shipments grew, the time and manpower required for inspection work became prohibitive, so there was a need to improve work efficiency. The company suggested automating the inspection process using RFID and chose us as a one-stop shop for flexible design, manufacture, installation and adjustment of tunnel gates.

Traditional barcode-based operations require barcodes to be read on every piece of every product, so the more items handled, the more time and manpower is required for receiving and shipping inspection.

Reading price tags is difficult when they are not in a visible position (hidden) or when multiple tags overlap. In some cases, when products are packaged in evaporated film, light is reflected from the film, making reading difficult.

Human error, such as missing or duplicate readings, is unavoidable, resulting in poor inventory accuracy.

The significant amount of time and manpower required for stocktaking causes delays in normal operations.

The tags inside can be read without opening the carton, whereas with barcodes it was necessary to open the carton and remove the goods.

Unlike barcodes, which can be difficult to read due to contamination, RFID can be read even when the surface is dirty.

Unlike barcode systems, which must be targeted and read one at a time, multiple tags can be read at once, allowing a large number of inspections to be completed instantly.

A serial number can be assigned in addition to the product code to allow individual item management for each item.

This can lead to more efficient management of individual items, quantities produced, and shipping and inspection operations.

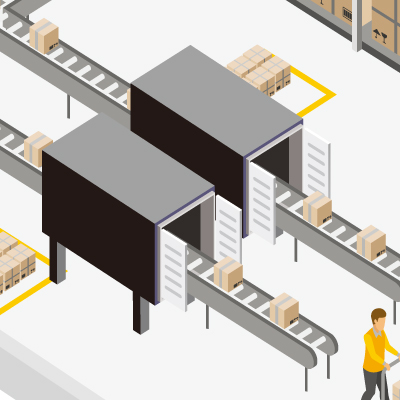

Tunnel-type batch readers allow the tags inside to be read in batches during conveyor transport without opening the packaging, automatically completing incoming and outgoing inspections.

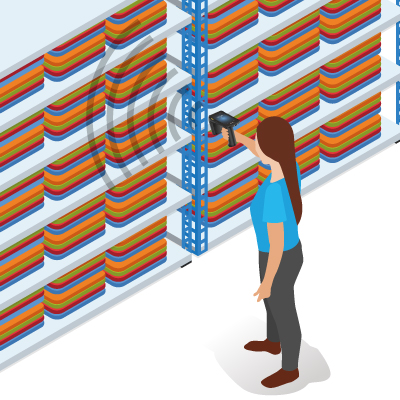

UHF handheld readers significantly reduce inventory work, which takes up a large proportion of sales staff time. Barcode reading, which used to be done on a piece-by-piece basis, can be reduced by around 90% by batch reading IC tags.

Automating the inbound and outbound inspection process has not only significantly reduced the time previously spent on this task, but has also eliminated human error.

The reduction in errors has improved the accuracy of inbound and outbound shipments in the factory, distribution centre and store channels.

RFID management has enabled detailed management of each item of clothing and clarified stock categories by allowing management of what is in which store, EC stock and store stock, as well as using the system for returns.

Manpower-saving in-store stocktaking and reimbursement processesBecause the reader can read products without their tags (barcodes) being visible, in-store stocktaking is significantly reduced. The reader can also be used to register products at the till, streamlining operations.

We have a wealth of information and expertise gained from inspecting many sites.

Based on this, we make the best suggestions for our customers and build a complete technical support system. If you have any questions, no matter how trivial, please do not hesitate to contact us.

A team of specialist engineers with extensive local experience will carry out the survey and installation, giving you peace of mind.

For enquiries about this product or service, or to discuss or consider its implementation, please contact us here.