Construction site access control using UHF RFID.

UHF RFID has enabled management of 'who moved where and when' by capturing information on the movement of workers. (A construction company)

UHF RFID has enabled management of 'who moved where and when' by capturing information on the movement of workers. (A construction company)

UHF RFID has made it possible to improve the efficiency and security of the management of important internal documents taken out of the company.

Is it difficult to understand the scanner commands and program the PLC?If you are using one of our PLC Link enabled scanners… you can set the scanner to the barcode data write memory address in the PLC and it will automatically write the read barcode data to the specified memory. Memory monitoring logic is all that is required. Of course, the read/write data is also handshaked with the PLC memory.Our industrial barcode/2D code scanner products come with PLC connectivity as standard.※Please contact our sales team for compatible models.

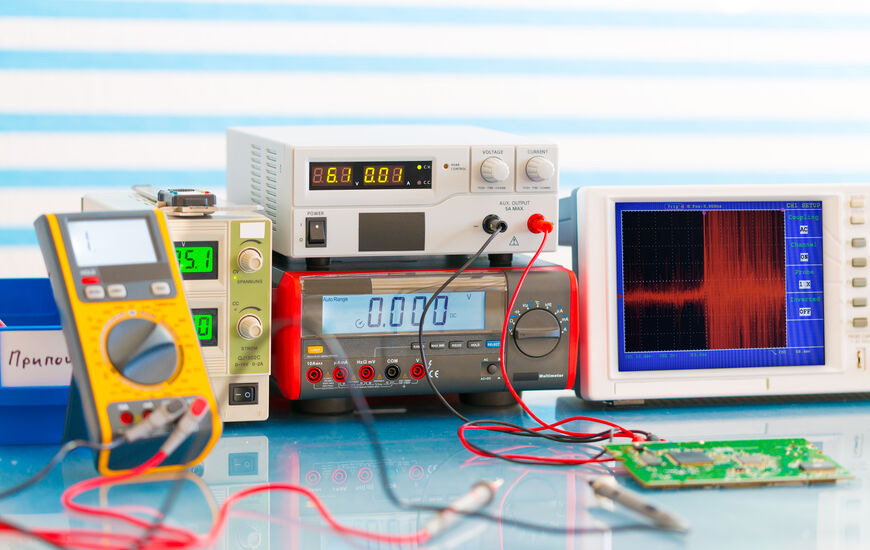

With the increasing density and integration of electronic devices, the control of electrostatic charge levels in the manufacturing process has become an important issue.In addition, many electronic devices, such as those used in automobiles, are used everywhere in our daily lives.Considering the damage that can be caused by the failure of electronic devices due to static electricity, ESD measures are now a must.

The use of UHF technology enabled easy individual management during the painting process, resulting in a reduction in human error and a shortened total operation time, leading to improved work efficiency. (Client from a certain manufacturing industry)At this factory, we managed each process by attaching a paper ledger (work instruction sheet) to the product, but problems such as illegible due to paper stains or incorrect attachment occurred, leading to a decrease in production efficiency. To prevent mistakes and improve production efficiency, we proposed the use of RFID technology, and our company provided one-stop support from selecting the UHF tag, providing hardware equipment, system development, to installation adjustment response.

We achieved centralized management of tool and measurement equipment usage history and batch reading using UHF RFID tags.This was implemented in railway and aviation services. Visual inspection of tools and equipment used to be conducted, but it became time-consuming due to a large number of management points. The use of RFID tags for checkout and return management was being considered to prevent tool misplacement and manage maintenance history. We proposed a one-stop solution, from selecting the UHF tag to providing hardware, system development, and installation adjustment support to address the challenges.

By using UHF-band RFID linen tags, we can read linen items such as uniforms and bed sheets, and achieve centralized management of usage counts, history management, and inbound/outbound inspections.In hotels and restaurants, linen items such as uniforms, bed sheets, and towels are collected by cleaning companies after use, and then new ones are delivered as needed. However, managing a large number of items is a challenge, and inspection work takes a lot of time. In addition, without serial management, it was difficult to determine the usage count that would serve as the disposal criteria, and measures against illegal possession and theft were not in place.By utilizing UHF-band RFID linen tags, bulk inspections of usage counts and delivery quantities become possible, leading to management of usage counts and prevention of theft through serial management.