Features/Functions

Automatic focus adjustment during tuning and installation

Automatic adjustment to set focus position and image processing.

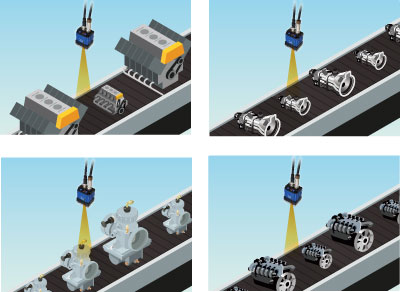

Multiple reading distances can be supported by a single unit

Stable readings in a mixed line of different sized workpieces.

The focus position of the symbol to be read can be automatically adjusted to ensure that symbols at different heights (distances) on the line can be read.

Convenient set-up function (memorises reading settings for each line)

The set-up function makes troublesome set-up changes easy

Reading settings for each line can be stored in advance and line-specific settings can be recalled instantly.

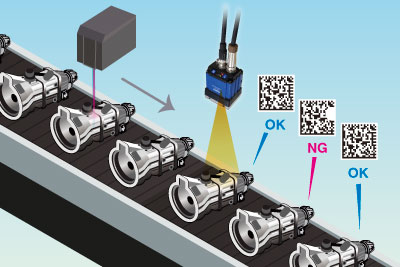

Print quality check function

Added barcode print verification functionality to improve operational efficiency and reliability

Real-time output of inspection results with ISO/IEC 15415 and ISO/IEC TR 29158 evaluation elements. Print quality can be determined inline. Verification results can be appended to the read data and output. Judgement based on inspection results can be output digitally OUT.

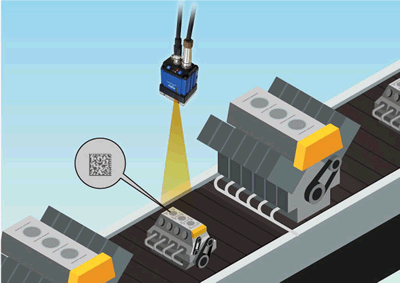

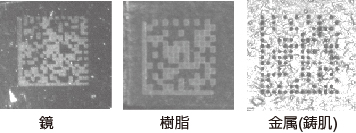

Ideal for reading direct markings

Ideal for reading symbols marked directly on a variety of materials such as metal and plastic parts. (also compatible with dot pens).

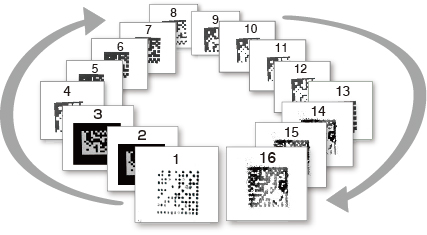

Intelligent table mode

The scanner has 16 preset reading conditions based on an analysis of print patterns that are considered difficult to read.

If the scanner cannot read with the active setting, it uses a unique algorithm to automatically select the optimum setting according to the reading focus. Equipped with an intelligent mode that remembers the selected reading settings and starts reading the next time!

You can also change the settings of up to 16 patterns.

Link without PLC programming! PLC link function

If the barcode data write memory address in the PLC is set in the scanner, the read barcode data is automatically written to the designated memory The programming of the PLC is only the memory monitoring logic, which is usually familiar to the designer. Of course, the read/write data is also handshaked using the PLC memory.

CC-Link IE field BASIC support

It can read, auto-adjust and set read/write from compatible PLCs.

Supported PLCs:MELSEC iQ-R/iQ-F/Q/L series, etc. Refer to the specifications of each PLC for details.

FTP Client Features

Images and readings can be sent via FTP.

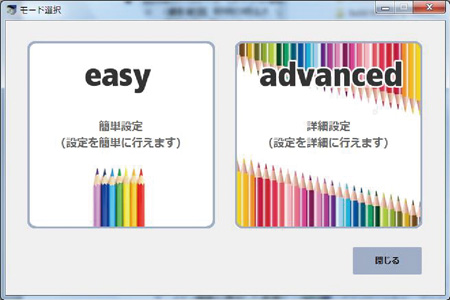

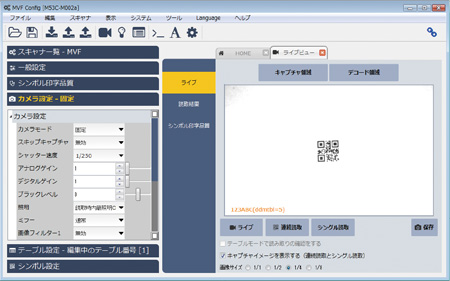

MCR Config software for easy setting of various parameters from a PC.

An ‘easy setup mode’ is available for anyone to use out of the box.

Reading parameters can be set automatically in the simple setting mode, making it easy for anyone to set up for symbol reading. Detailed parameter settings can also be made in the detailed setting mode, which covers all configurable functions.

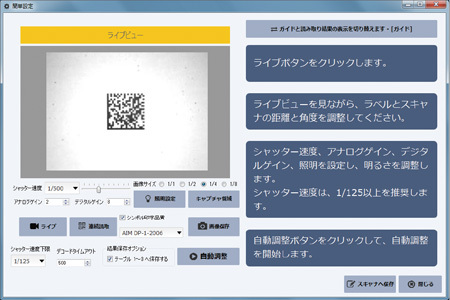

Displays the image read by the scanner.

Adjustment – allows you to view the image and adjust it according to the on-screen instructions. The adjustment parameters can be saved as a file on your computer.

Advanced setup mode

While checking the image on the live screen, change the displayed parameter items so that the corresponding image is displayed. If you change the shutter speed, analogue gain, digital gain, black level, etc., the changes are reflected on the live screen in real time.

Introduction video

Product Specification

| model | MCR-F530 | |

|---|---|---|

| Photosensor | Image Sensor | 1/3″ CMOS image sensor B&W |

| Number of effective pixels | 1280 (X) x 960 (Y) (approx. 1.2 million pixels) | |

| focus | Auto (allows automatic adjustment of focus position during installation and tuning) | |

| luminous part | Illumination Light source | High intensity white LED |

| Pointer light source | Laser pointer (red) | |

| Corresponding symbols | 1D Code | Codabar , Code39 , Code128/GS1-128 ,Code93 , GS1 DataBar , ITF , UPC/EAN/JAN |

| 2D Code | Data Matrix (ECC) , QR Code/Micro QR | |

| Reading angle | PITCH: ±35° / SKEW: ±35° / TILT: 360°. | |

| Min. resolution | 0.1 mm | |

| Reading Distance | 100 ~ 500 mm | |

| Reading field of view (at 300mm) | 91 x 68mm | |

| Power supply rating | Supply voltage | DC power supply: 24 V DC ± 10% (scanner connector: power input) |

| PoE power supply: Type A/B, 36-57 V DC (LAN connector) *Not available with DC power supply system. | ||

| Current consumption | DC power supply: in command (synchronous) standby: approx. 150 mA / in read operation: approx. 450 mA | |

| PoE power feed Power class 3 | ||

| Digital input | Photocoupler isolation x 1 point Input resistance : 1 kΩ OFF voltage : 0 to 0.8 V, ON voltage : 6 to 28 V | |

| Digital output | Photocoupler isolation x 3 points Maximum rating 30 V DC 50 mA | |

| Interface | Ethernet (10Base-T、100Base-TX) | |

| RS-232C(1200bps ~ 115.2kbps) | ||

| environmental friendliness | Operating temperature | 0 ~ 40℃ |

| 動作湿度 | 35 – 85%R.H. (no condensation) | |

| Storage temperature | -20 ~ 60℃ | |

| Vibration resistant | 10-55 Hz Amplitude 1.5 mm (full width)/X, Y, Z 2 hours in each direction | |

| protective structure | IP67 | |

| Ambient illuminance | 10000 lx max. | |

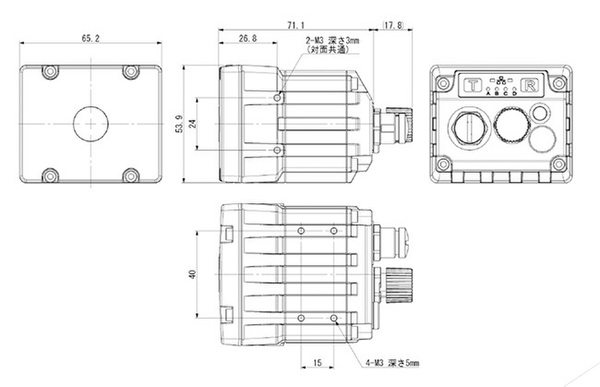

| Outer dimensions | 71.1(H) × 65.2(W) × 53.9(D)mm | |

| weight | Approx. 320 g | |

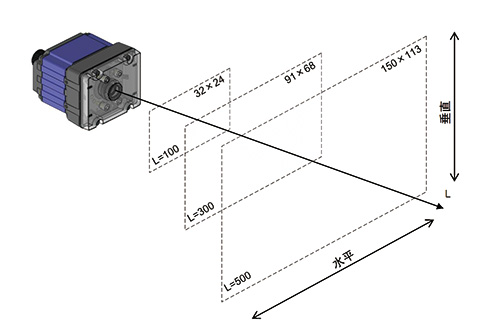

Reading Distance

| Cell Sizes | near-field | far-field |

|---|---|---|

| 0.10 | 100 | 125 |

| 0.125 | 100 | 155 |

| 0.167 | 100 | 215 |

| 0.19 | 100 | 245 |

| 0.25 | 100 | 325 |

| 0.33 | 100 | 430 |

| 0.38 | 100 | 500 |

View width/distance (reading area)

| Distance | 100 | 200 | 300 | 400 | 500 |

|---|---|---|---|---|---|

| horizontality | 32 | 62 | 91 | 121 | 150 |

| vertical | 24 | 40 | 46 | 68 | 113 |

Outer dimensions

Click on the button to open the image.

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.