Features/Functions

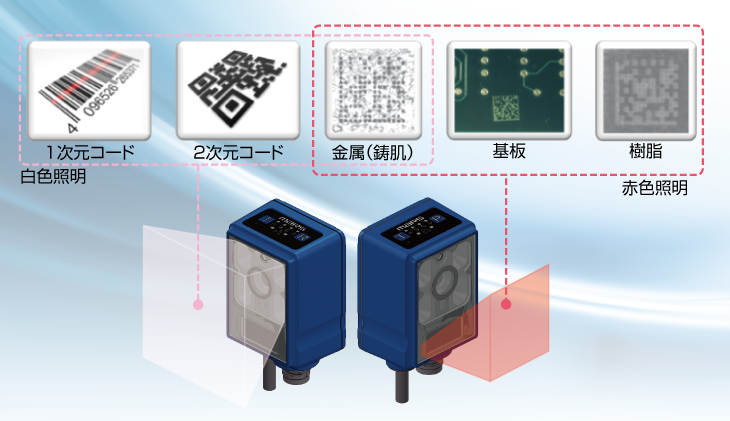

Two lighting modes for accurate readings

High-intensity white and red oblique illumination provides optimum reading conditions for the subject and mounting position.

- White lighting:Codes on less reflective materials such as paper

- Red light:DPM (direct part marking) codes on metals, resins, substrates, etc.

Equipped with a high-resolution 1.2-megapixel CMOS sensor

The high-resolution 1.2 megapixel CMOS enables clear imaging of previously difficult-to-read codes and symbols.

The system can also be tuned in the reading area for any illumination, enabling fast, highly accurate reading of previously difficult-to-read symbols.

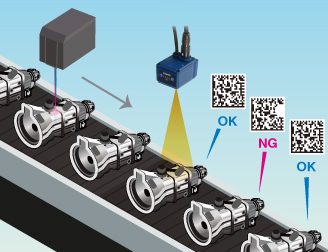

Excellent mobile readability

Equipped with new logic designed specifically for moving measurements. Together with the improved high-brightness illumination and high-resolution CMOS sensor, it supports faster moving reads. 1D/2D codes moving along a line can be read with unprecedented speed and accuracy.

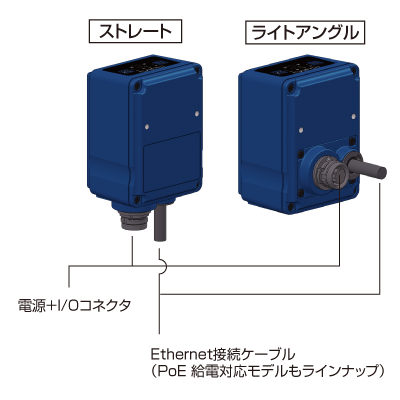

Compact, two cable mounting options

Compact and straight (MCR-F180-ST) and right angle (MCR-F180-RA) models are available. They can be used in a variety of installation situations and are ideal for equipment integration.

Object Detection (Paper Detection)

This function detects the reading object and executes the reading operation. In addition to the conventional object detection method, an infrared laser method has been added. You can select which method of detection to use depending on your environment.

Easy position adjustment using only the main unit

The pointer and LEDs inform the user of the correct distance using the new object detection function. The mounting position is easy to adjust.

Supplied with software for reading configuration

MCRConfig2, which allows various parameters to be easily set from a PC.

This software for Windows allows various settings and tables to be operated via a GUI.

It allows you to make automatic adjustments with simple operations and to check the readings.

PLC link function for connection to PLC without programming.

The PLC Link function automatically writes the read barcode data to the specified memory, which is often used in FA (Factory Automation) sites.

Print quality check function

Added barcode print verification functionality to improve operational efficiency and reliability.

Real-time output of inspection results with ISO/IEC 15415 and ISO/IEC TR 29158 evaluation elements. Print quality can be determined inline. Verification results can be appended to the read data and output. Judgement based on inspection results can be output digitally OUT.

Introduction video

Product Specification

| model | MCR-F180/A/R/AR models | MCR-F180P/AP model | ||

|---|---|---|---|---|

| Photosensor | Image Sensor | 1/3-inch CMOS image sensor Monochrome | ||

| Number of effective pixels | 1280(X)×960(Y) (approx. 1.2 million pixels) | |||

| luminous part | Illumination Light Sources | High intensity white LEDs, high intensity red LEDs 625nm | ||

| Pointer light source | Blue LED 470nm | |||

| Corresponding symbols | 1D and 2D | Code39, Code128/GS1-128(EAN128), Codabar(NW7), ITF(Interleaved 2 of 5), UPC/EAN/JAN, GS1 DataBar(RSS), Code93, Data Matrix(ECC200), CompositeCode, QR Code/Micro QR Code, PDF417/MicroPDF, AztecCode | ||

| Reading angle | PITCH: ±35° / SKEW: ±35° / TILT: 360°. | |||

| 250mW(24dBm) | ||||

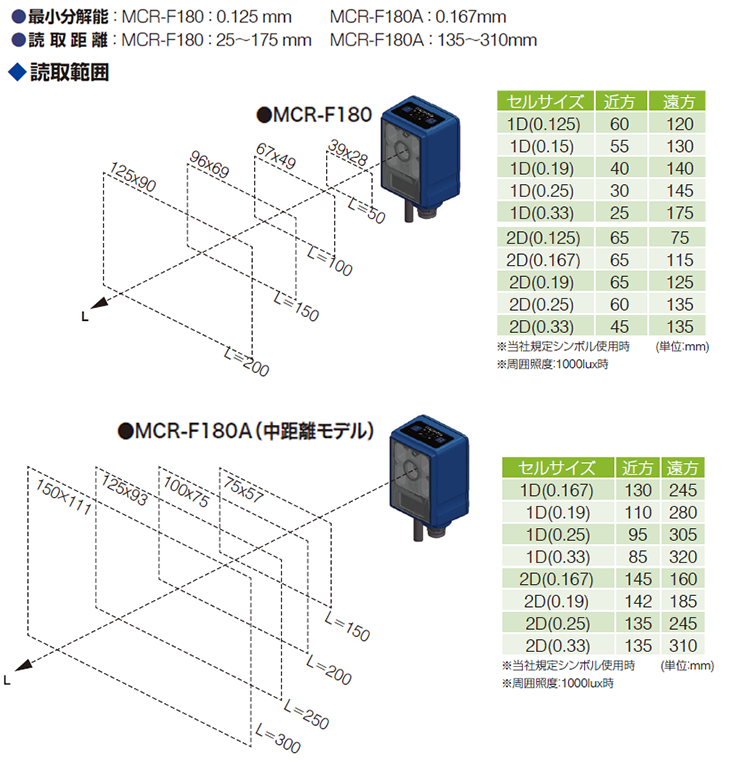

| Min. resolution | MCR-F180 : 0.125mm MCR-F180A : 0.167mm | |||

| Reading distance | MCR-F180:25~175 mm MCR-F180A:85~320mm | |||

| Reading field of view (at 100mm) | 71×53mm | |||

| Power supply rating | Supply voltage | DC power supply: 24 VDC ±10%. | DC power supply: 24 V DC ± 10%. PoE power supply: Type A only. ※DC and PoE cannot be used together. |

|

| Current consumption | DC power supply: in standby approx. 150 mA During reading: approx. 400 mA |

DC power supply: Standby: approx. 150 mA During reading: approx. 400 mA PoE power supply: Class 3 |

||

| Proximity sensor | Infrared Laser 940nm Class 1 | |||

| Digital input | Photocoupler isolation x 1 point Input resistance: 2.2 kΩ | |||

| OFF voltage: 0 to 0.8 V, ON voltage: 10.8 to 28 V | ||||

| Digital output | Photocoupler isolation x 2 points (F180/A/P/AP models), photocoupler isolation x 1 point (R/AR models) Maximum rating 30 V DC 50 mA | |||

| Interface |

Ethernet (100BASE-TX, 10BASE-Te)/RS-232C(R/ARのみ) Ethernet (100BASE-TX, 10BASE-Te)/RS-232C (R/AR only) |

|||

| environmental friendliness | Operating temperature | 0~40℃ | ||

| Operating humidity | 35-85% R.H. (no condensation). | |||

| Storage temperature | -20~+60℃ | |||

| Storage humidity | 35-85% R.H. (no condensation). | |||

| Vibration resistant | 10-55 Hz Amplitude 1.5 mm (total width)/X, Y, Z each direction for 2 hours | |||

| protective structure | IP67 | |||

| Ambient illuminance | Less than 10000 lx | |||

| Outer dimensions | 60(H)×45(W)×35(D)mm (Excluding protruding parts) | |||

| weight | Approx. 220g | Approx. 235 g | ||

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.