Features/Functions

Electrostatic Discharge (ESD) Models

We are one of the few manufacturers who have been involved in the research and development of Anti-Electrostatic Discharge models for many years.

Countermeasures against the destruction and degradation of microcontrollers due to ESD have become an essential item in the manufacturing of electronic components, including liquid crystal devices, and are attracting the attention of finished product manufacturers as an important item for reliability assessment.

Our anti-ESD scanners use materials that are carbon-free, have low ionic contamination and low outgassing, and incorporate new technologies.

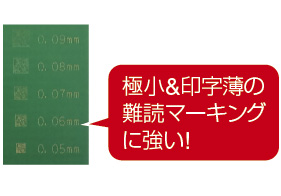

Ideal for reading direct markings.

Ideal for reading 2D symbols directly marked on printed circuit boards, plastic components, etc., this system brings together MTS’s unique cutting-edge expertise and enables the reading of direct markings that were previously considered difficult to read.

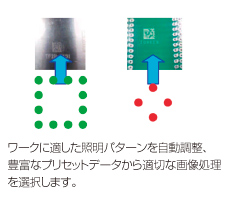

Easy reading setup at the touch of a button.

Produces optimal images for 2D symbol analysis Easy to set optimal illumination settings

Unique lighting functions allow free lighting settings for a wide range of workpieces, including substrates, metals and LCDs.

Easy set-up with intelligent auto-tuning function (※1) and simple set-up software. This frees you from the tedious tuning work associated with direct marking.

※1:The MCR-H700 selects the appropriate process from preset data. It meets the need for immediate use, with only button operation on the main unit.

Wide viewing window for easy targeting

Previously, it was difficult to aim at the small 2D symbols beyond the scanner, but thanks to the large reading window, it is now easier to aim and read.

Easy to use configuration tool allows anyone to make the optimum settings.

You can easily find the optimum settings by selecting the illumination and image processing while viewing the readout image in real time.

The Table Mode function allows you to set the default readout settings for a wide range of materials, so in most cases you won’t need to make any settings at all.

Equipped with PLC link function (RS-232C model)

If the barcode data write memory address in the PLC is set in the scanner, the read barcode data is automatically written to the designated memory The programming of the PLC is only the memory monitoring logic, which is usually familiar to the designer. Of course, the read/write data is also handshaked using the PLC memory.

Wireless (Bluetooth) models now available

読み取り結果を無線(Bluetooth通信)でホストPCに送信できるため、読み取り範囲の制限を軽減し、操作性を向上させることができます。

Maximum Bluetooth range (reference values) : Approx. 10 m at sight.

※Varies depending on obstacles (e.g. human bodies, metal walls, etc.) and radio wave conditions.

※Charging table (MBC-700) and AC adapter sold separately.

※Bluetooth receiver (MBA-300) sold separately.

The MCR-H710 model is now available to handle ‘detached reading’ and ‘wide barcodes’ in a single unit

The DPM (Direct Part Marking) readers had to be read close to the workpiece, as they are equipped with special lighting to enable reading of markings with poor print quality.

The reading range was also limited due to the close reading distance to the part.

◎ I can’t get the scanner to read the part close to the DPM, e.g. uneven castings!

◎I want my DPM scanner to read wide slip barcodes!

The MCR-H710 is a DPM scanner, but it can also handle ‘detached reading’ and ‘wide barcodes’ in a single unit.

※Depending on the minimum resolution and reading difficulty, only the MCR-H700 may be able to cope.

Ideal for reading 2D symbols marked directly on printed circuit boards and glass surfaces. It can handle even smaller marks than conventional machines.

Lowest resolution 40μm(0.04mm)

※Up to 25 µm is possible with the use of attachments (sold separately).

Introduction video

Product Specification

| model | MCR-H700/710/720-ESD Series |

|---|---|

| Interfaces | RS-232C model/USB & HID model/Bluetooth Class2 model. ※MCR-H720 is only available in USB & HID and Bluetooth models. |

| Application Code | 2D Code: Data Matrix(ECC200)、QR Code、Micro QR Code |

| 1D Code: Code39、Code128/GS1-128 (EAN128)、Codabar(NW7)、ITF(interleaved 2of5)、JAN/EAN/UPC、GS1 DataBar、Code93 | |

| Image Sensor | 1/3″ CMOS B/W 1280(X)×960(Y) (approx. 1.2 million pixels) |

| Current consumption | RS-232C models: approx. 400 mA |

| USB & HID models & Bluetooth Class 2 models: Approx. 1500 mA (with charging cradle installed) Approx. 400 mA (with USB cable connected) | |

| Operating temperature/humidity | 10-40°C (during charging)/ 0-40°C (during normal use)/ 35-85%RH (no condensation) |

| Storage temperature/humidity | -20 to 60°C /35 to 85%RH (no condensation) |

| protective structure | IP64 |

| Shock and vibration resistance | Normal operation after being dropped onto concrete from a height of 1.5 m. However, external damage is excluded. |

| Outer dimensions | MCR-H700/710:199(H)×80(W)×142(D)mm, MCR-H720:216(H)×80(W)×152(D)mm |

| weight | MCR-H700/710: 315 g (not including cable) / Bluetooth model :380 g (including battery) |

| MCR-H720: 365g (excluding cable) / Bluetooth model: 430g (including battery) | |

| Surface resistance | 105Ω~108Ω |

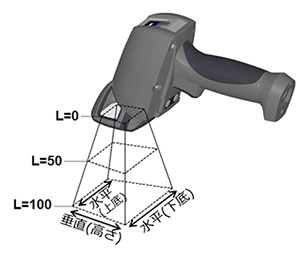

Reading Distance

| 【MCR-H700-ESD】 Depends on the minimum cell size (see below) 18-27 mm (cell size 0.1 mm:) / 0-30 mm (cell size 0.125 mm and above) |

| 【MCR-H710-ESD】 Depends on the minimum cell size (see below) Barcodes: 0-70 mm (cell size 0.125 mm), 0-100 mm (0.25 mm) 2D codes (QR): 10 – 35 mm (cell size 0.167 mm), 0 – 60 mm (0.25 mm) |

Viewing width/distance (reading area)

【MCR-H700-ESD】

| Reading distance | 0mm | 30mm |

|---|---|---|

| Horizontality | 32mm | 44mm |

| Vertical (height) | 24mm | 34mm |

【MCR-H710-ESD】

| Reading Distance | 0mm | 20mm | 50mm | 70mm | 100mm |

|---|---|---|---|---|---|

| Horizontal (top bottom) | 34mm | 44mm | 56mm | 66mm | 80mm |

| Horizontal (lower bottom) | 44mm | 56mm | 74mm | 86mm | 108mm |

| Vertical (height) | 30mm | 37mm | 48mm | 56mm | 70mm |

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.