Vision systems that enable small starts.

It is said that the key to advancing DX is to start small. Vision systems are generally expensive to install, but MTS vision systems with simple hardware configurations make it possible to start small. The MTS vision system can also be used for large area vision inspection at low cost. Please do not hesitate to contact us first by referring to the ‘Introduction Flow’ below.

MoMaVi is ideal for clients who

- “Industrial cameras”, “special lighting” and “image inspection equipment” are over-specified.

- There is no budget to install machine vision in each of the multi-product structures.

- I want to test whether easy detection and recognition is possible.

Features/Functions.

Various inspections available

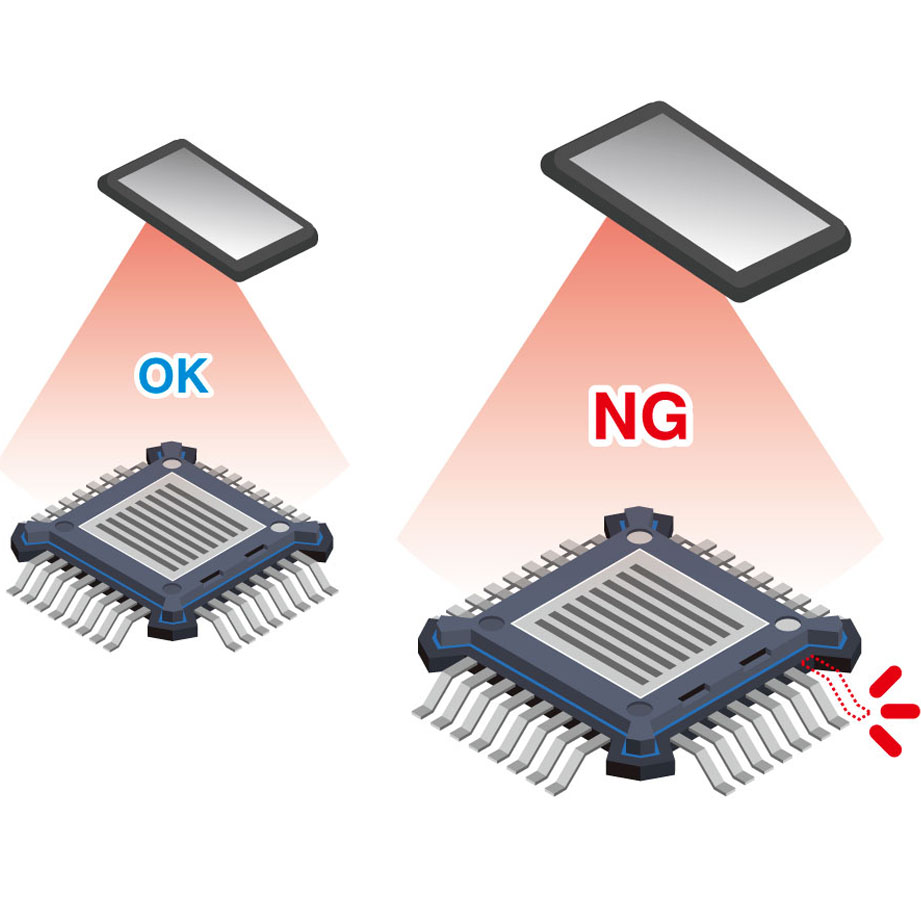

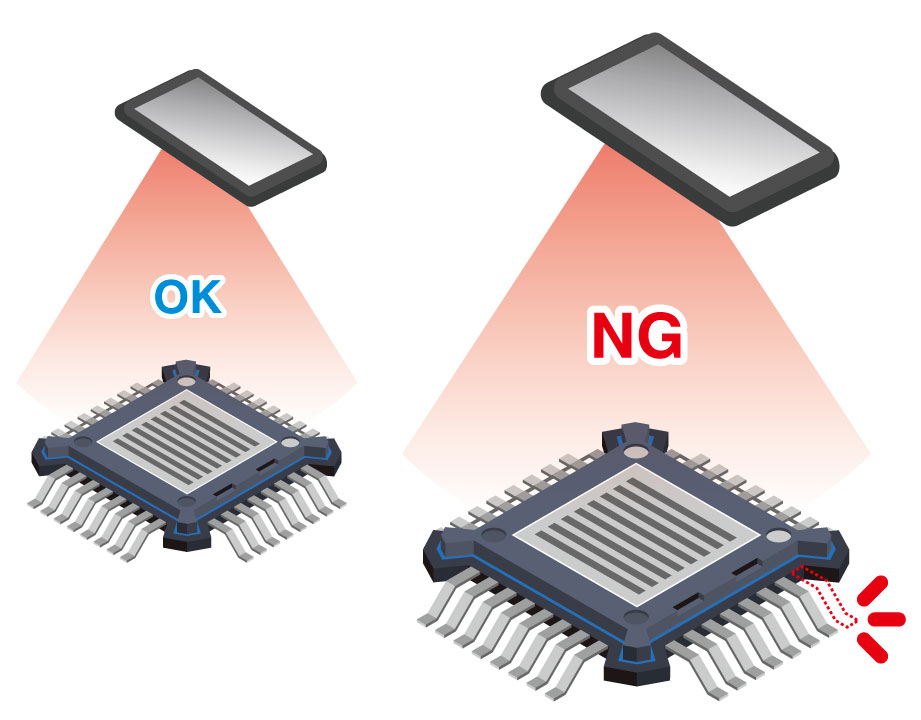

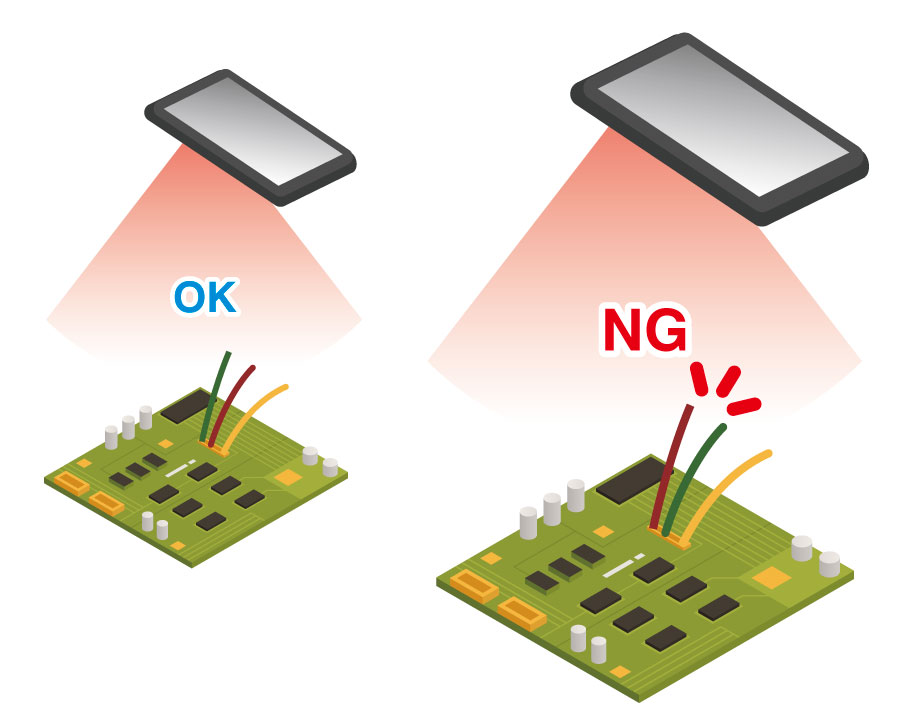

Presence check

Checking for the presence or absence of what should be there.

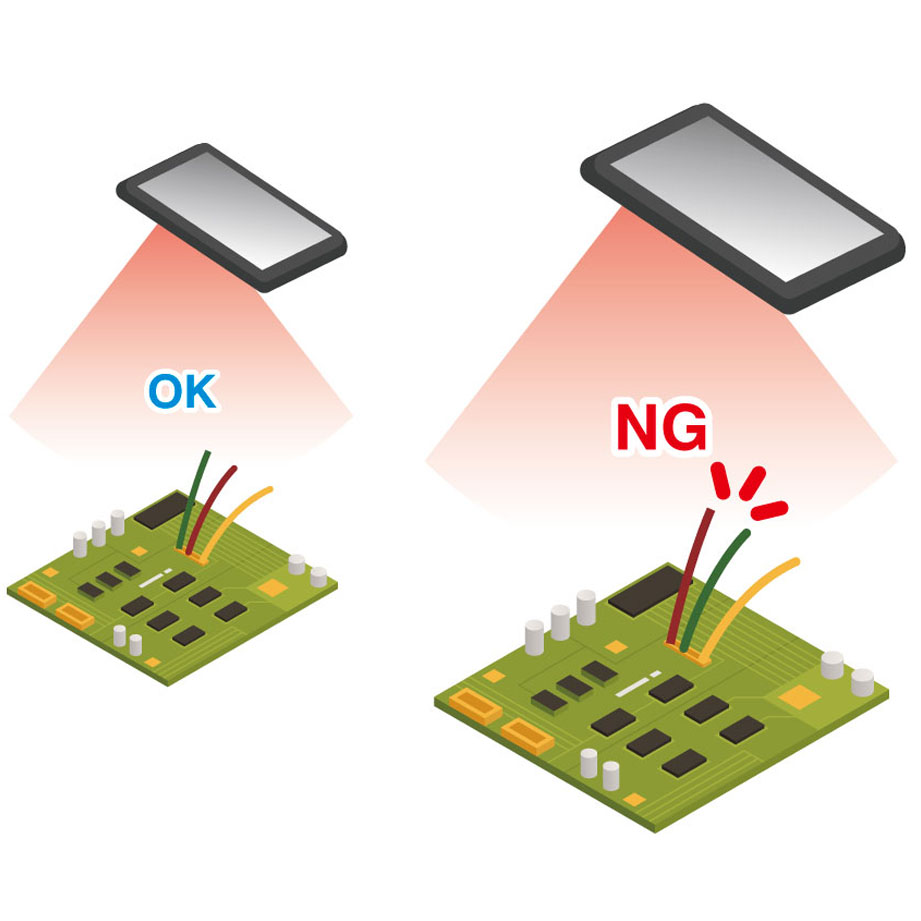

Colour sequence check

Check that different coloured parts are in the correct order, etc. (connectors, wiring harness, etc.)

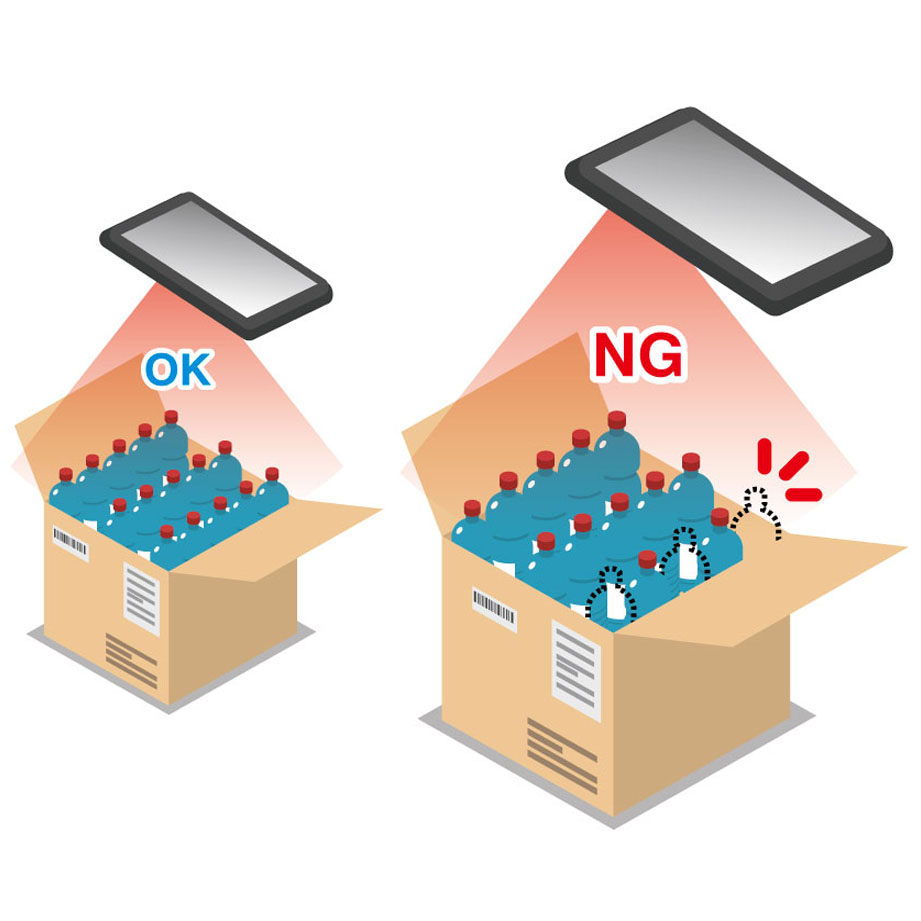

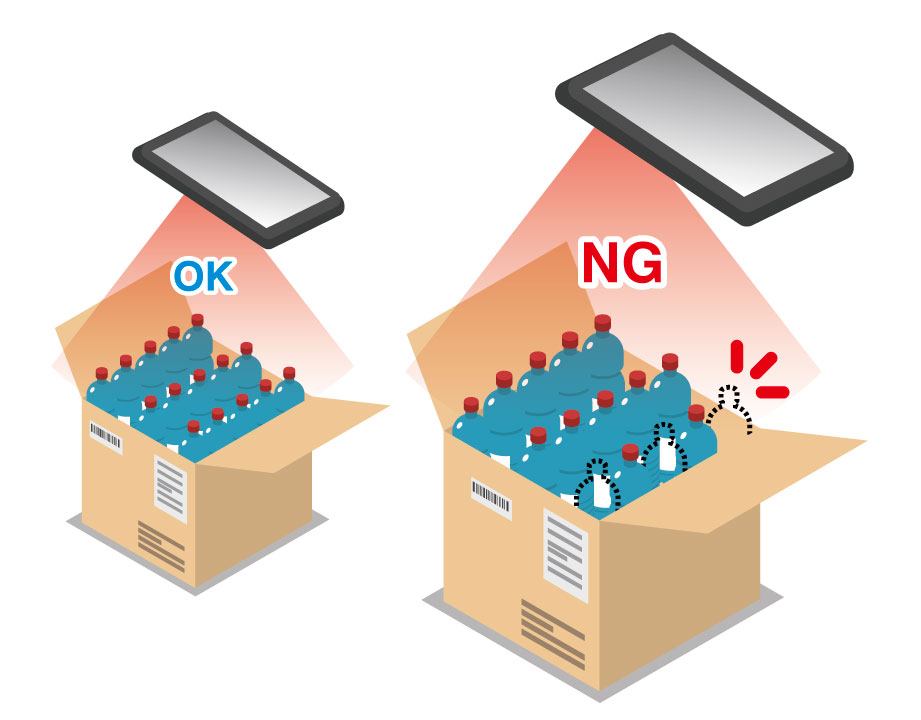

Quantity counts.

Checking the quantity of items in boxes and pallets.

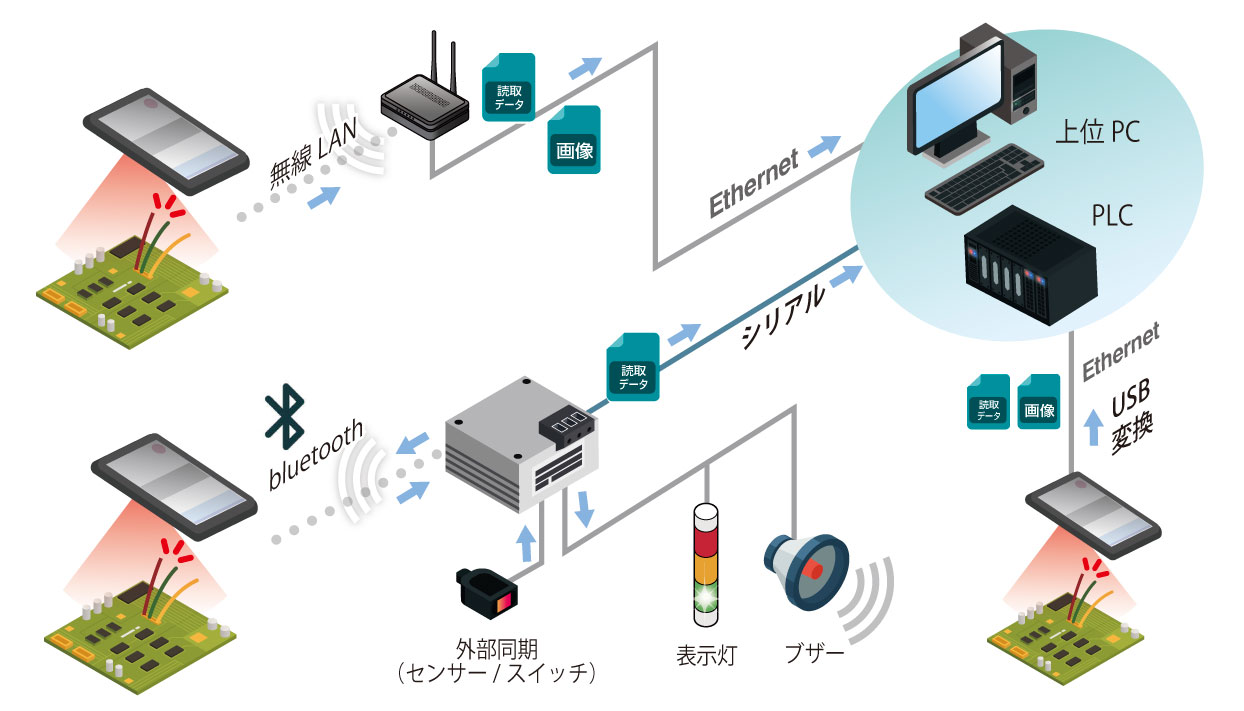

Sample configurations and system overview

Introduction video

For enquiries about this product or to discuss its implementation, please click here.

Implementation process (items and procedures to be checked on site).

The following checklist may be useful to facilitate the induction study.

*For inspection items, it may not be possible to deal with minute details that cannot be visually identified or described.

Inspection method

- Presence check

- colour check

- Sequence check

- Quantity Count

- Pattern Recognition

- Shape/orientation inspection

Subject identification

This item is used to determine the size and material to be inspected and to specify the required specifications and configuration.

For example, it is necessary to check what inspections are currently being carried out.

- Inspection area (range)

- Inspection object size

- Material (metal/resin/paper)

- State (fixed/mobile)

- Inspection criteria (OK/NG)

Environmental controls

The environment and conditions at the time of the inspection are determined and the content of the system is specified.

Example: Inspection load from one direction only|Inspection from multiple directions possible|Personnel can provide assistance such as aligning the direction of the object.

Conditions such as those listed above should be checked.

Communication System

- Cable LAN

- Wireless LAN

- USB

- RS-232C

Reading distance

Camera and subject positioning

Devices to communicate with

Read verification

Workpiece loan

- OK

- NG

field test

- OK

- NG

Other.

Current/past situation.

Data processing method

The results of the readings need to be checked for data processing methods such as [I want to save (NG only/all) images], [I want to save text strings], [I need to judge OK/NG only], [I want to return a specific command at a higher level].