What is VisAI-Edge?

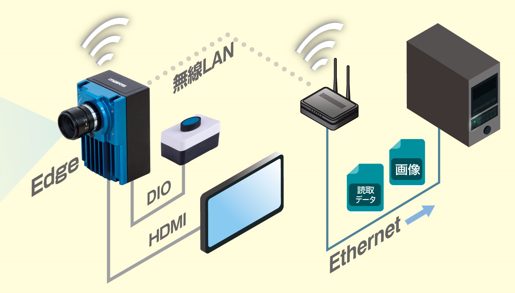

VisAI-Edge is an edge AI device equipped with standard industrial interfaces and a C-mount. It can be command-controlled from an upper-level host system.

For users seeking an even simpler setup, we also offer “Vision System for Smartphone – MoMaVi“, which comes with the same shared application.。

Features & Functions

Low-Cost Feasibility Testing

Use the smartphone version as a trial device

By utilizing the smartphone-based version “MoMaVi,” equipped with the same VisAI application, users can perform initial feasibility tests. This helps visualize whether the system will work smoothly upon implementation, what operational changes can be expected post-installation, and what level of effectiveness is likely—enabling more efficient and impactful adoption.

Subscription plans available

We also offer flexible subscription plans that make initial implementation more accessible. Please contact our sales team for details.

Easy Inspection Setup with a Simple GUI

3-Step Inspection Setup

One of VisAI’s key strengths is its ease of use—even without programming or deep learning expertise. Its intuitive GUI (Graphical User Interface) has been highly praised by many users. Basic setup can be completed in just three steps:

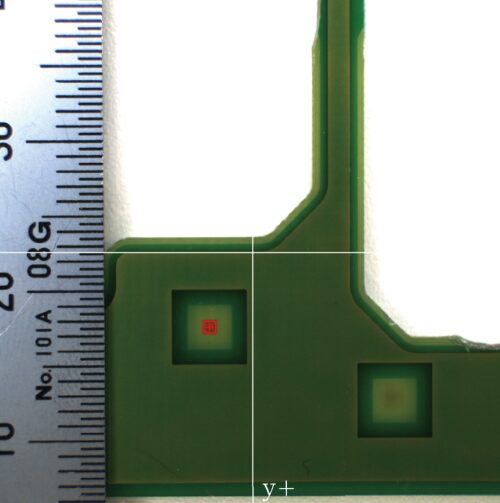

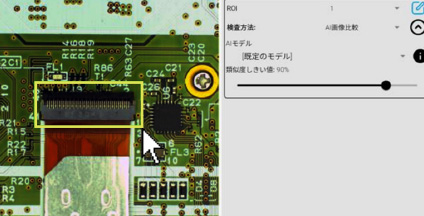

- Use the camera to capture the target object and drag to specify the inspection area (ROI) on screen

- Select the appropriate inspection method from a dropdown menu

- Set pass/fail thresholds or configure how the system processes the read data according to the selected method

Useful Features to Improve Efficiency

Scenario Registration

Multiple inspection setups can be saved as individual “scenarios,” which can be recalled with a single touch when needed.

AI Model Creation Tool (Optional))

Although pre-trained models for AI image comparison (deep learning) are included, we also offer the “VisAI Training” tool, which enables users to create custom AI models for more precise inspections. With its easy-to-understand GUI, even users without technical backgrounds can develop and deploy their own models in-house.

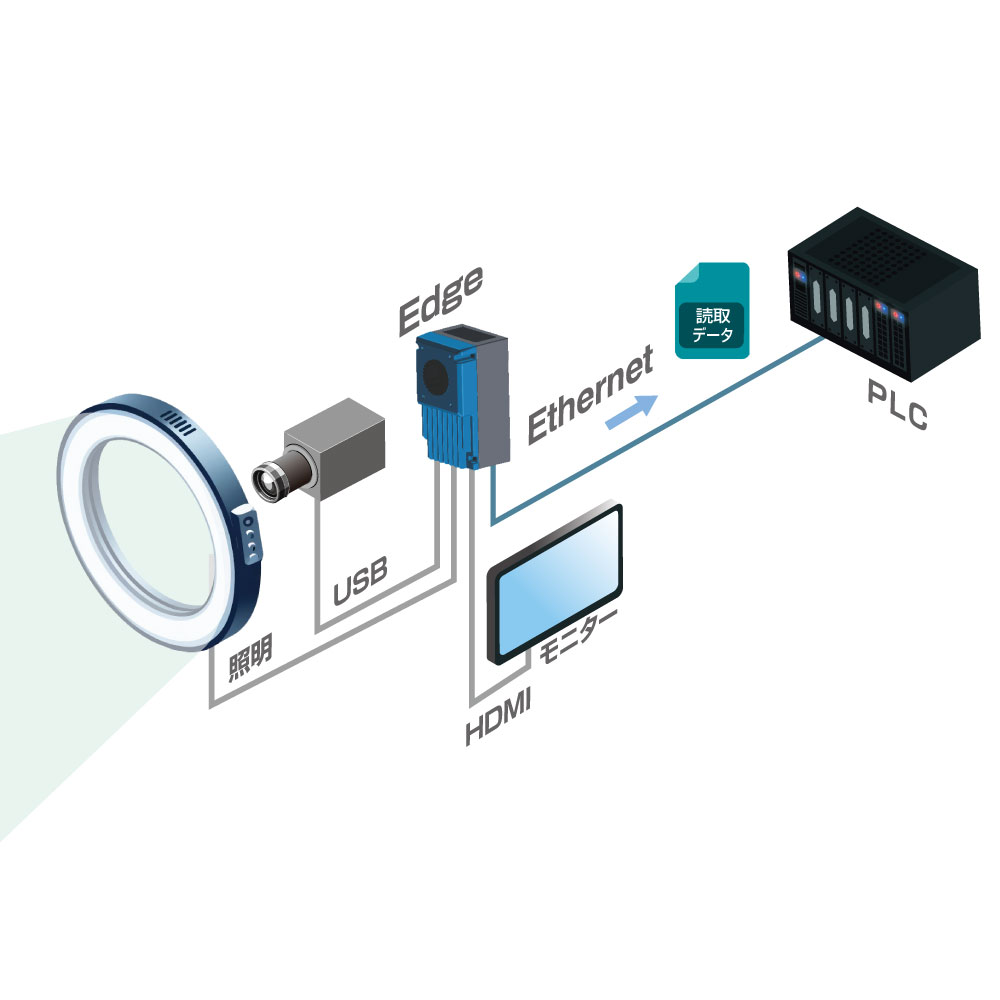

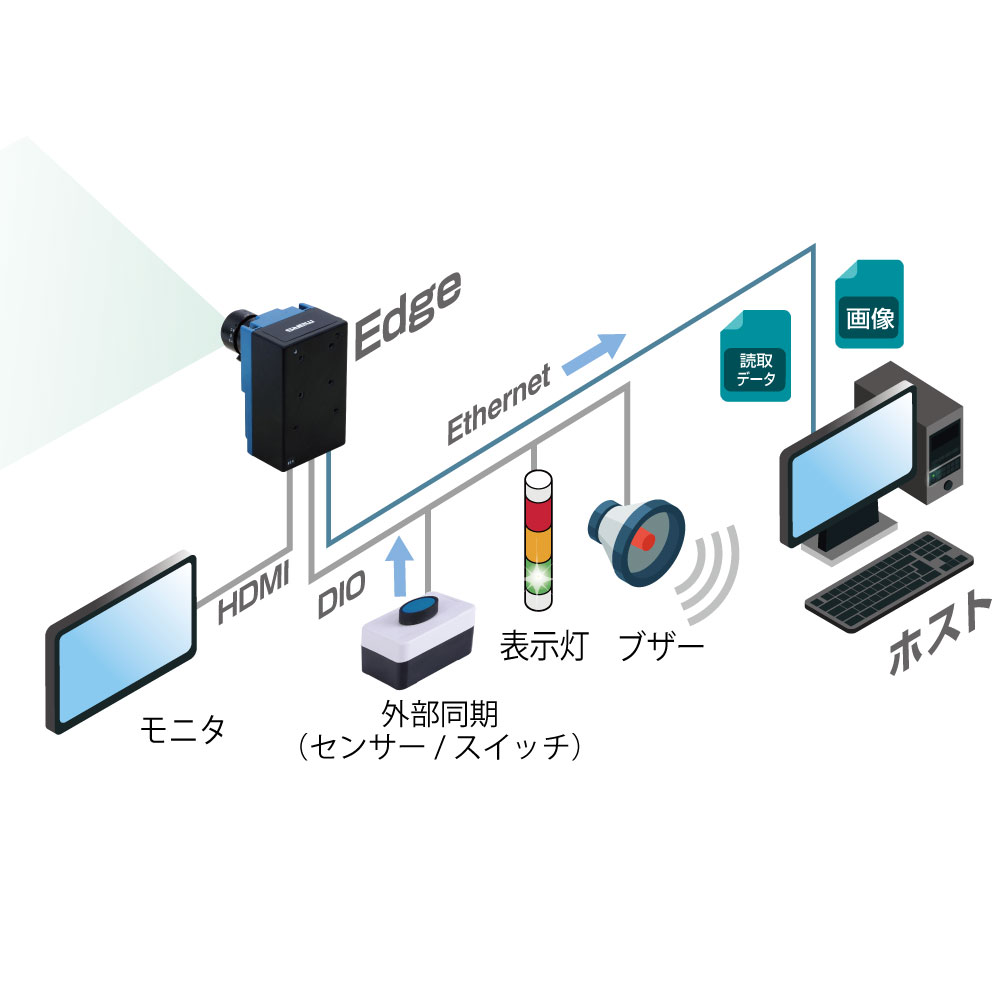

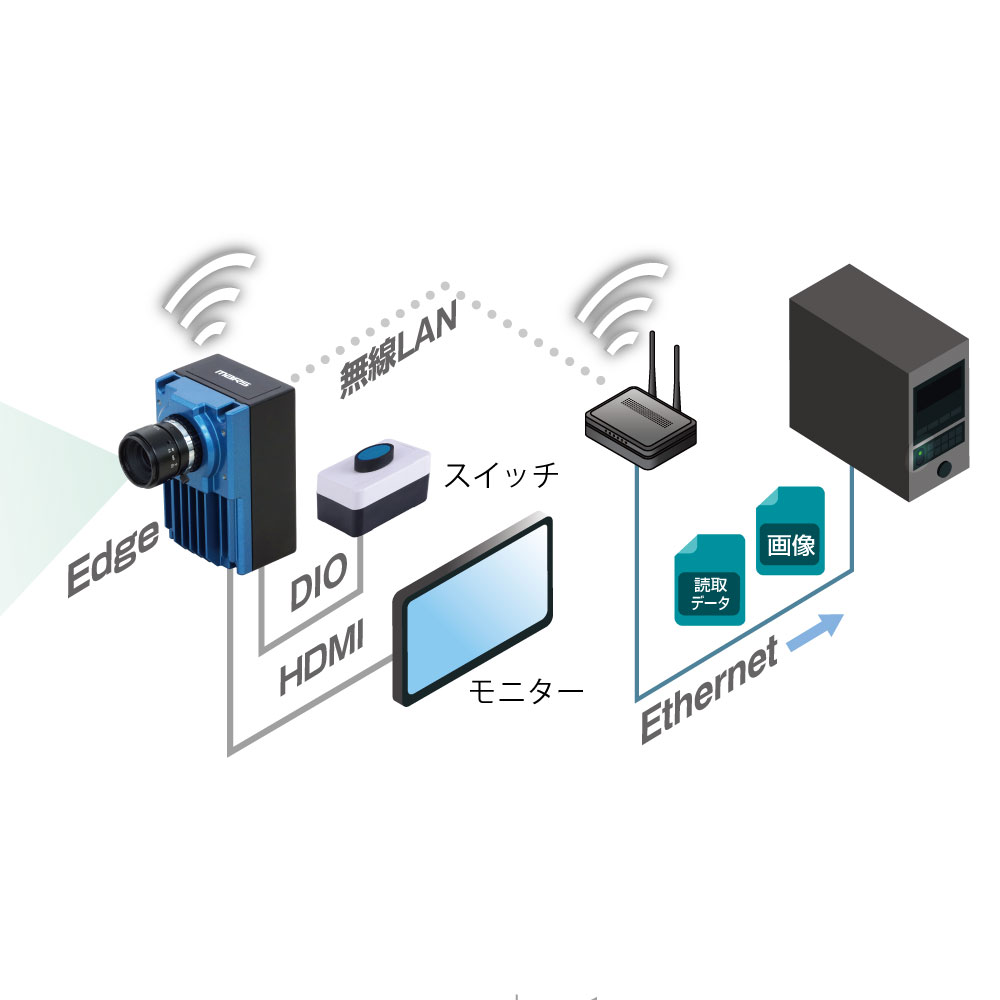

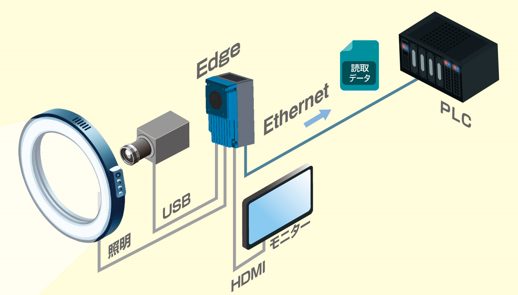

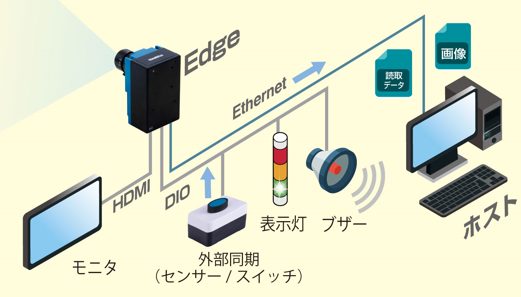

Supports Various System Configurations

Command connection from upper-level host system

Wi-Fi connection

USB connection

Digital I/O (DIO) integration

What VisAI-Edge Can Do

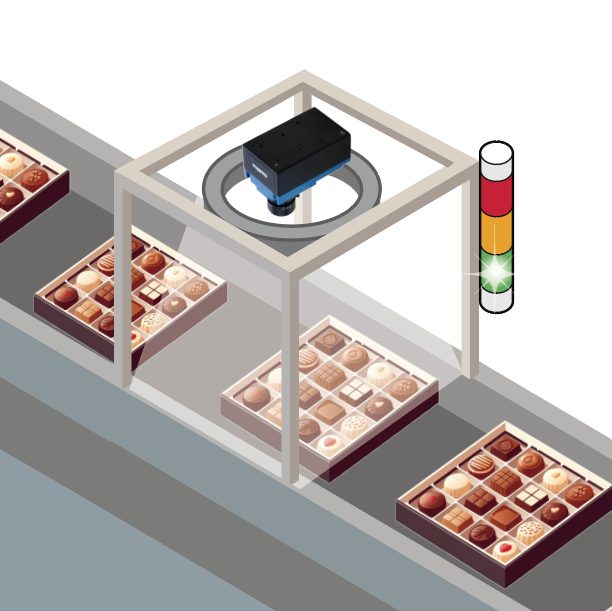

Shape Inspection of Products and Parts

Use Case: Component Set Verification

Determines whether parts are correctly attached or assembled, and distinguishes between acceptable and defective products or components.

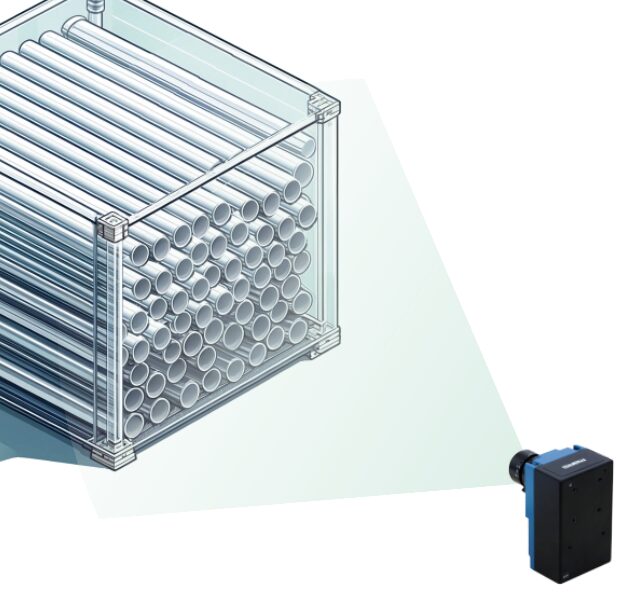

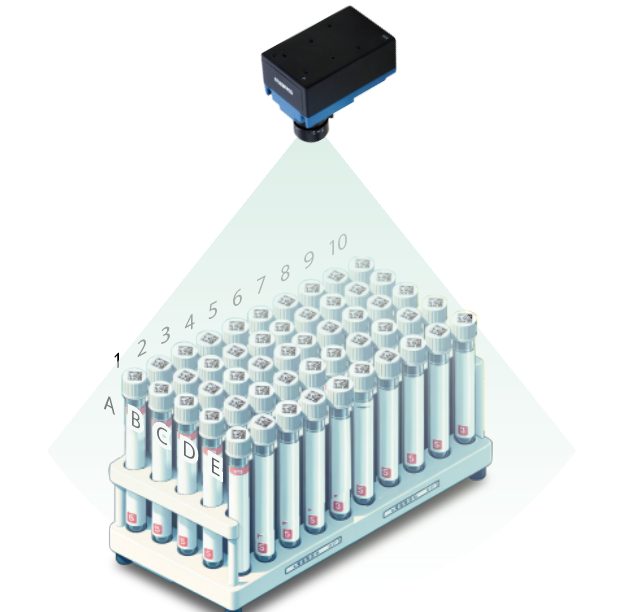

Barcode Reading (Bulk Scanning Supported)

Use Case: Bulk Barcode Scanning

Reads and verifies multiple barcodes printed on or attached to products, labels, or nameplates—all at once, even when directly printed or engraved.

Frequently Asked Questions About VisAI-Edge

Here you can find commonly asked questions about VisAI‑Edge, presented in a convenient Q&A format.

VisAI-Edge is dedicated industrial-grade hardware, equipped with a 12-megapixel sensor, C-mount lens compatibility, industrial I/O, and built-in external lighting control. It is ideal for high-speed, stable, permanent installation on production lines.

It offers industrial-level reliability with features such as noise resistance, long-duration operation, and a heat-dissipating aluminum die-cast enclosure.

Yes. Since VisAI‑Edge supports C‑mount lenses, you can choose lenses tailored to your on-site requirements—such as telecentric, macro, or wide-angle types—as well as coaxial, ring, or bar-type lighting options.

For 12-megapixel images, inference takes approximately 0.2 to 0.5 seconds; for HD images, it’s less than 0.1 second.

With a built-in GPU, VisAI-Edge can handle multiple inspections simultaneously.

- LAN: 1× Gigabit Ethernet

- Wi-Fi: Wi-Fi 5

- USB: 3× USB 3.2 Type-A, 1× USB 3.2 Type-C

- Bluetooth: 5.0

- DIO: 2 inputs / 3 outputs (optically isolated)

- HDMI: 1 port

- Also includes a dedicated terminal for external lighting

Operating conditions: 0–40°C, 10–55 Hz, 1.5 mm vibration on each XYZ axis for 1 hour.

For harsher environments, custom enclosure options are available.

Supports TCP commands, REST API, and OPC-UA gateway.

Successfully integrated with MES/WMS systems and direct PLC control in previous installations.

Images are first saved on a PC → trained using VisAI Training → then the updated model is transferred to VisAI‑Edge via USB or FTP.

An optional redundant storage configuration (SSD RAID 1) is available.

OK/NG inspection statistics can be exported in real time as CSV files and synchronized with the cloud.

For enquiries about this product or to discuss its implementation, please click here.

Implementation process (items and procedures to be checked on site).

The following checklist may be useful to facilitate the induction study.

*For inspection items, it may not be possible to deal with minute details that cannot be visually identified or described.

Inspection method

- Presence check

- colour check

- Sequence check

- Quantity Count

- Pattern Recognition

- Shape/orientation inspection

Subject identification

This item is used to determine the size and material to be inspected and to specify the required specifications and configuration.

For example, it is necessary to check what inspections are currently being carried out.

- Inspection area (range)

- Inspection object size

- Material (metal/resin/paper)

- State (fixed/mobile)

- Inspection criteria (OK/NG)

Environmental controls

The environment and conditions at the time of the inspection are determined and the content of the system is specified.

Example: Inspection load from one direction only|Inspection from multiple directions possible|Personnel can provide assistance such as aligning the direction of the object.

Conditions such as those listed above should be checked.

Communication System

- Cable LAN

- Wireless LAN

- USB

- RS-232C

Reading distance

Camera and subject positioning

Devices to communicate with

Read verification

Workpiece loan

- OK

- NG

field test

- OK

- NG

Other.

Current/past situation.

Data processing method

The results of the readings need to be checked for data processing methods such as [I want to save (NG only/all) images], [I want to save text strings], [I need to judge OK/NG only], [I want to return a specific command at a higher level].

Specification

Item | Specification |

|---|---|

Display | 1 x HDMI with CEC hardware ready |

Interfaces | Wired LAN: 10Base-T, 100Base-TX, 1000Base-T |

USB Ports | 3 × USB 3.2 Gen 1 Type-A ports |

Indicators | Ready: Orange |

Buzzer | Yes |

I/O | Input: SYNC × 2 |

Power Supply Voltage | DC 24V / 2.5A |

External Lighting Output | DC 24V / 1A |

Readable Symbols | Decoder: CortexDecoder |

Environmental Resistance | Operating Temperature: 0 to 40°C |

Operating Humidity: 40 to 85% R.H. | |

Storage Temperature: -20 to 65°C | |

Storage Humidity: 35 to 85% R.H. | |

Dust/Water Resistance: IP30 | |

Vibration Resistance: 10–55 Hz, amplitude 1.5 mm (peak-to-peak), | |

Ambient Illumination: Up to 10,000 lx | |

External Dimensions | 60.6 (W) × 52.0 (D) × 96.5 (H) mm (excluding protrusions) |

Weight | 400g |

※Cマウントレンズはオプション