Pre-introduction issues

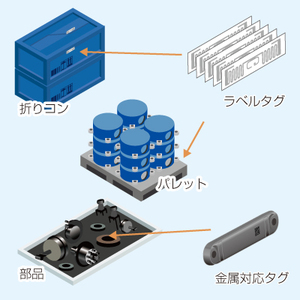

Control of movement of parts and products

Work instructions move with the product parts. It is difficult to obtain accurate process information in real time due to the workload and errors associated with reading barcodes on work instructions.

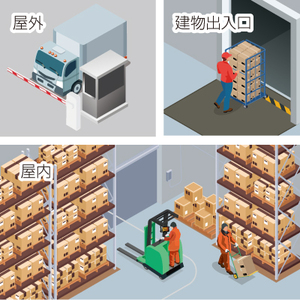

Management of inbound and outbound trucks

Loading details for inbound and outbound trucks rely on barcode reading and visual confirmation at the time of loading, which still makes it difficult to obtain accurate, real-time information on inbound and outbound shipments.

Inefficiency of instructions due to lack of visibility of the truck’s operating status

Difficulty in efficiently issuing instructions from the office due to lack of real-time information on the status of forklifts moving to the shipping location…

Pre-implementation considerations

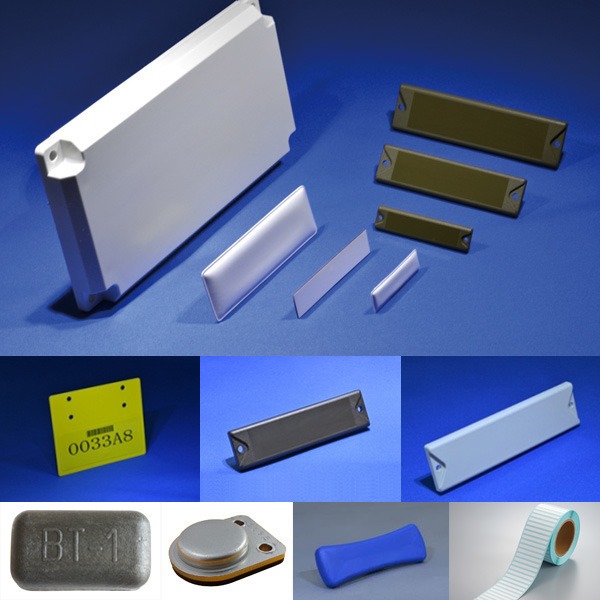

Checks the content of the read target and selects UHF tags.

When selecting an IC tag, we will propose the most suitable one according to various conditions, such as the target material (metal, plastic, wood, paper, cloth, human, etc.), the mounting method (adhesive, screws, tapes, etc.), the size of the tag, whether surface printing is required, the required environmental resistance performance (temperature, humidity, shock, etc.) and the price.

Checking the reading environment

After carrying out various read-related checks, the system is verified in the same environment as the actual operation to ensure that the IC tags and RFID devices to be used fulfil their intended role. We make system proposals, including the selection of appropriate equipment, after carrying out a preliminary survey before making a proposal.

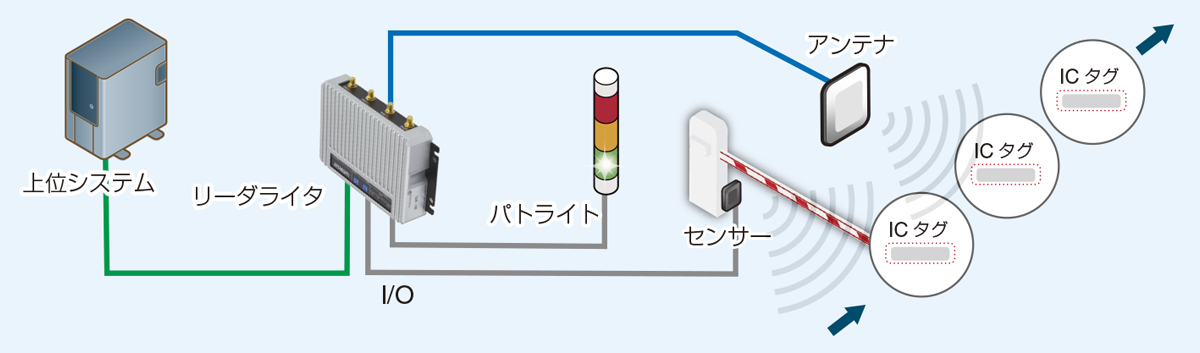

System example

Advantages of implementation

Improved efficiency of management tasks

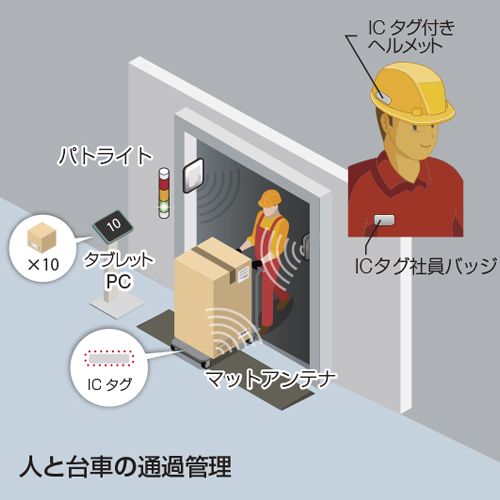

This eliminates the need for visual checks and barcode reading by operators, reducing their workload and eliminating errors.

information real-time management

The information read by the reader/writer is transmitted to a higher level system, allowing the administrator to understand the information in real time.

Whereabouts management

Installing antennas at transit points during movement allows movement records to be collected, resulting in reliable location management.

Reduced inspection time

Inspection times can be significantly reduced by using UHF RFID, which can read multiple IC tags simultaneously.

Improved inventory accuracy

This eliminates errors such as missing visual checks by operators and failing to read barcodes, and improves inventory accuracy.

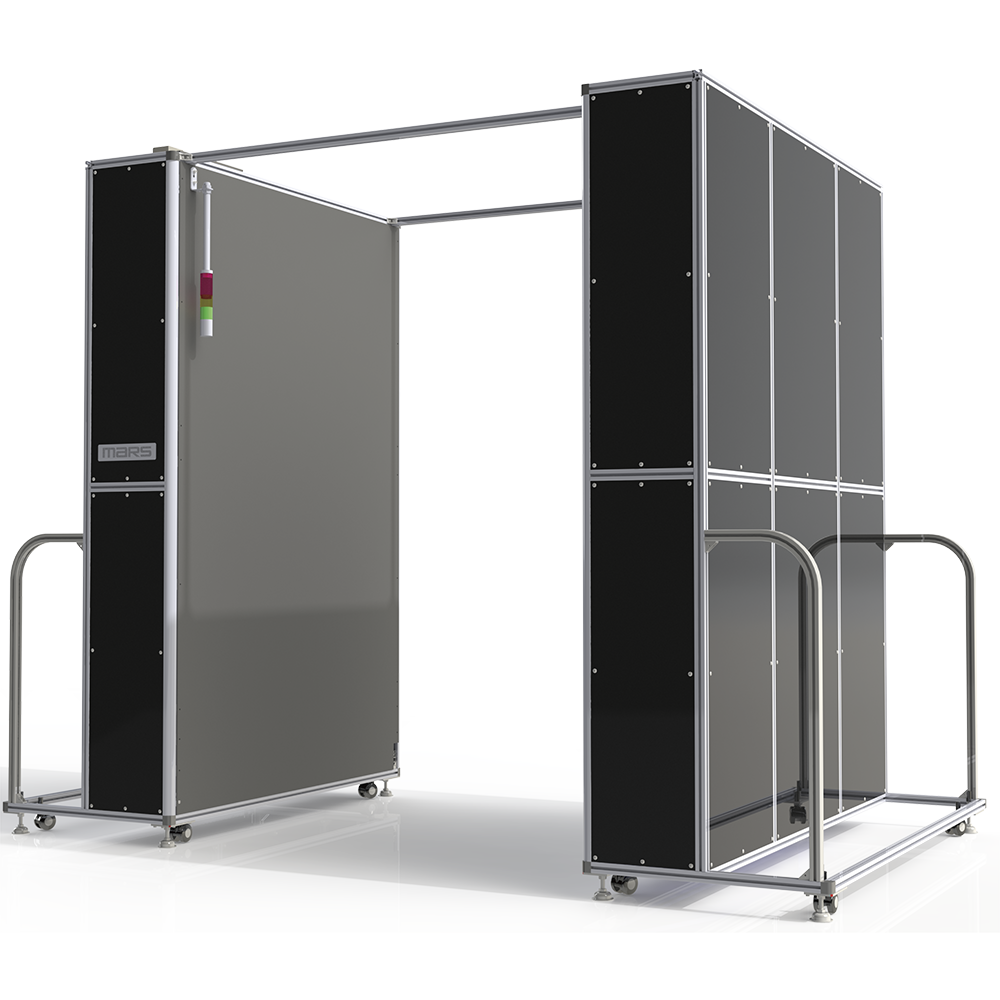

Examples of UHF gates in use at various sites

導入までの流れ

RFID導入実績多数。安心してお任せいただけます。

当社には数々の現場を確認し蓄積してきた豊富な情報・ノウハウがあります。

それをもとにお客様にとって最適なご提案と共に、万全のテクニカルサポート体制を構築します。どんな些細なことでも不明点があればお気軽にご相談ください。

Introduction flow

Many RFID installations. You can rely on us.

We have a wealth of information and expertise gained from inspecting many sites.

Based on this, we make the best suggestions for our customers and build a complete technical support system. If you have any questions, no matter how trivial, please do not hesitate to contact us.

MTS pre-introduction consultancy

Introduction flow

- Customer enquiries.

- requirements hearing

- rough estimate

- On-site survey

- Formal quotation

- Equipment and system installation

A team of specialist engineers with extensive local experience will carry out the survey and installation, giving you peace of mind.

- Choice of IC tags and hardware equipment

- System proposals

- Suggestions for site improvements