Challenges in Conventional Assembly Inspection

- Manual inspection leads to inconsistencies in quality.

- Inspection tasks require significant time and labor costs.

- Limited inspection accuracy poses a risk of overlooking defective products.

To address these challenges, the implementation of a high-precision automated inspection system was essential.

Implementation Solution

Automatically verify the correct arrangement of sweets in trays inline.

Judges correctness based on presence/absence, color, and shape sequence.

Supports CSV output of inspection results; “OK” and “NG” images are automatically saved.

Inspections are triggered automatically within the software using the auto-trigger function.

Implementation Benefits

| Item | Improvement Details |

|---|---|

| Inspection Accuracy Improvement | mproved defect detection rate, significantly reducing errors. |

| Work Efficiency Enhancement | Greatly reduced time required for the inspection process. |

| Cost Reduction | No need for dedicated equipment, lowering initial investment and operational costs. |

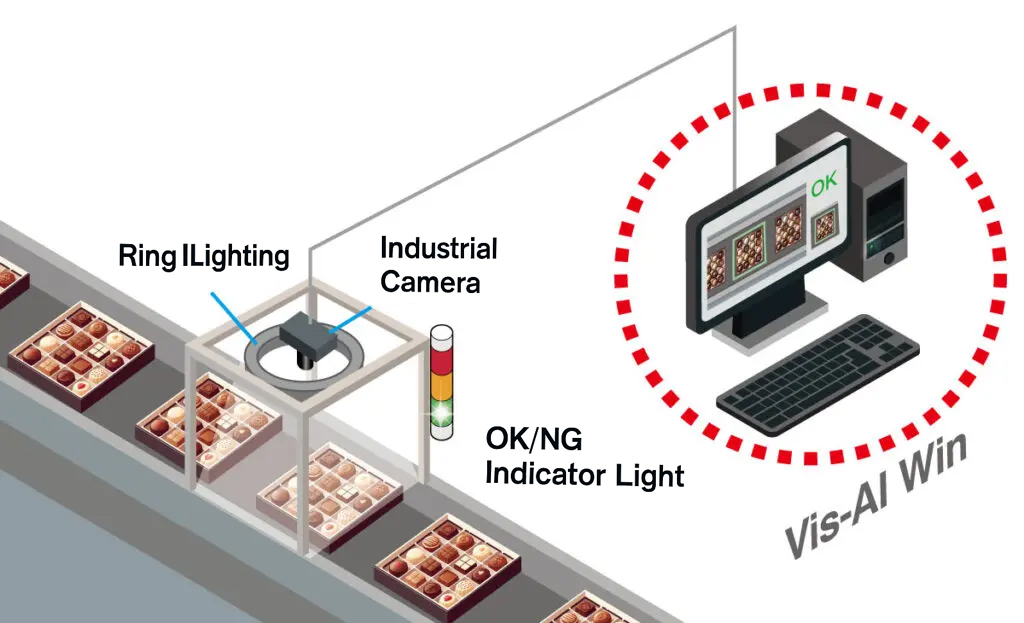

AI Vision System “Vis-AI” Series with Shared Application

The Vis-AI series of AI vision systems is equipped with the VisAI shared application and offers a range of options tailored to specific use cases, including the necessary interfaces, processing capabilities, and durability.

The lineup includes:

- MoMaVi – a smartphone-based solution for easy and low-cost implementation

- VisAI-Edge – an edge AI device with standard industrial interfaces

- VisAI-Win – ideal for more demanding processing tasks and seamless integration with other applications