Features/Functions

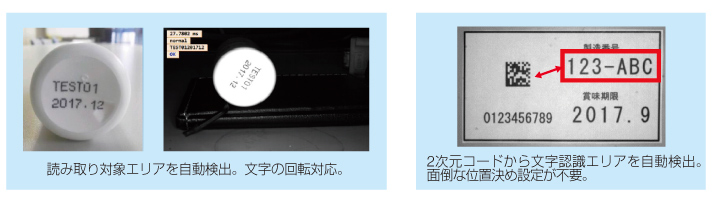

OCR(Character recognition)

As well as reading barcodes, it is now possible to read character printouts such as expiry dates, lot numbers and manufacturing symbols.

The character recognition function enables checking of production dates and expiry dates due to date setting errors and the recording of additional information such as lot numbers and production symbols as traceability information.

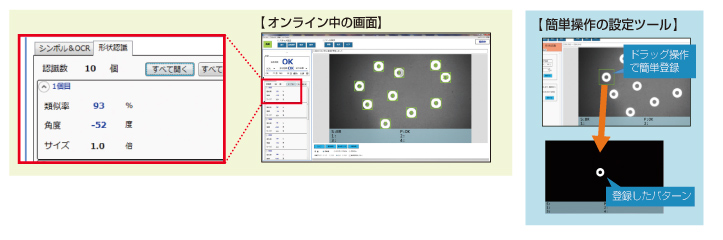

Pattern matching (shape recognition)

Decision thresholds can be set for number of patterns read, angle and similarity rate. (e.g. OK if the similarity rate is 80% or more).

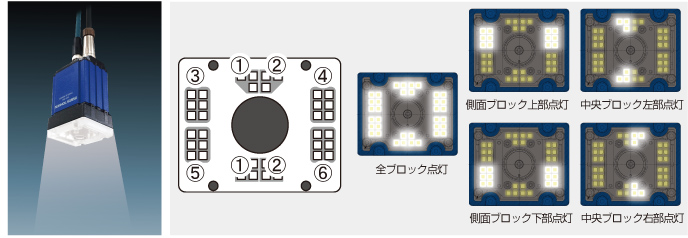

Lighting features for easy reading

Optimum lighting according to material and environment for a wide range of reading scenarios.

Flexible lighting settings are possible with two blocks in the centre (①②) and four blocks on either side (③④⑤⑥), giving a total of six blocks, each of which can be set to be lit or unlit. High reading performance is achieved with optimum lighting to suit the material, environment and shape. This single unit can be used for a wide range of difficult-to-read parts.

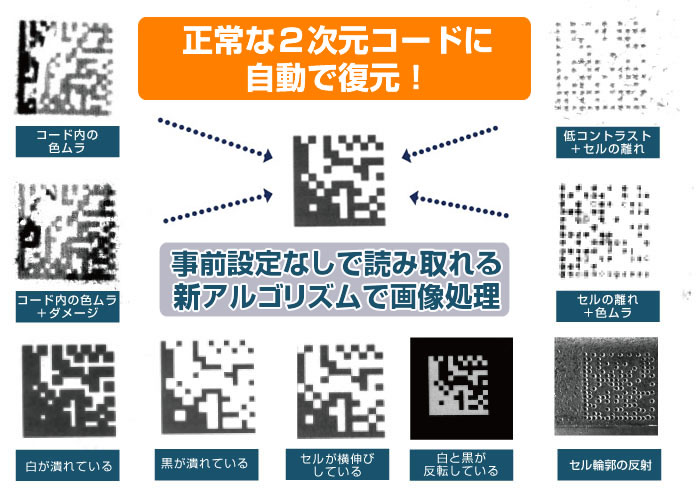

Equipped with a new algorithm

New reading capability for damaged symbols that were difficult to read and unreadable by conventional machines, such as colour irregularities within the symbol, low contrast and distant cells. Cell squashing, lateral stretching and smearing can also be automatically restored during reading without pre-setting using a new algorithm.

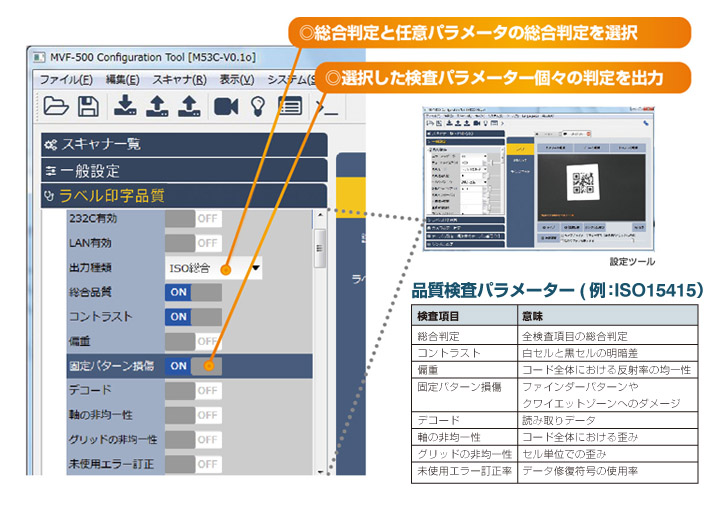

Print quality inspection function

※Output of inspection results with ISO 15415 and AIM DPM 2006-1 evaluation items.

By checking the print quality according to standardised rules, stable barcode reading is possible not only for the company itself, but also for the entire supply chain, including the delivery destination. In addition, in-line print quality monitoring can provide immediate warning of print defects or changes in the age of the marking equipment immediately after marking. Quality can be inspected at the same time as the barcode is read, according to the parameters of the ISO 15415 and AIM DPM 2006-1 international standards.

The inspection results can be output not only as an overall judgement as required by ISO and AIM, but also as a judgement by arbitrarily selecting the inspection parameters that suit the actual operation.

Deep margin essential for readability

Readability cannot be judged solely on the basis of catalogue specifications measured in the best position. The “reading depth” is also a very important factor.

The optimum combination of a newly developed sensor and lens and a new type of illumination ensures high reading performance over a wide range of focal lengths.

The MVF-500C also offers excellent reading performance over a wide range of conditions, including reading distance, symbol density and workpiece material colour, with a free choice of C-mount lenses.

Intelligent table mode

Eight patterns of reading conditions are preset in the scanner, based on an analysis of print patterns that are considered difficult to read.

If the scanner cannot read with active tuning, it automatically selects the best reading setting from the eight patterns for optimum reading.

Equipped with an intelligent mode that remembers the selected reading settings and starts reading the next time!

The settings of up to 8 patterns can also be changed at will.

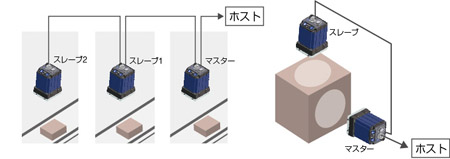

Connect without a controller! Multiple connection

The MVF-500 allows multiple scanners to be linked together, making it ideal for applications where a larger area needs to be covered or where barcodes are printed in multiple directions.

In addition, the scanner itself can be reconfigured to act as either a master or slave, eliminating the need for a keypad to control multiple units. In an emergency, it is easy to switch to an alternative unit.

PLC programless connection!

If the barcode data write memory address in the PLC is set in the scanner, the read barcode data is automatically written to the specified memory.

The programming of the PLC is just the memory monitoring logic that you are used to developing.

Of course, data exclusive control is also handshaked using the PLC memory.

Connection to Mitsubishi Electric, OMRON and Keyence PLCs is supported as standard.

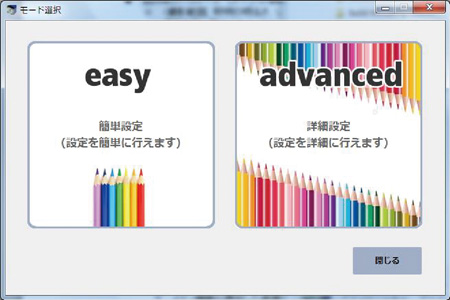

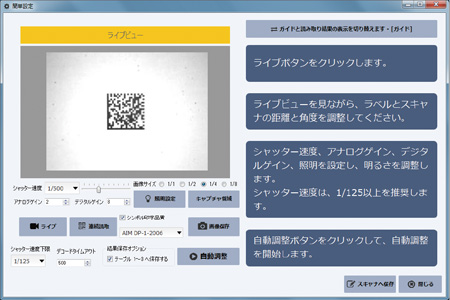

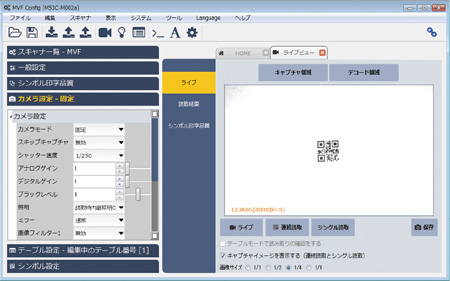

MVFConfig software for easy setting of various parameters from a PC

An ‘easy set-up mode’ is available for anyone to use immediately.

Reading parameters can be set automatically in the simple setting mode, making it easy for anyone to set up for symbol reading. Detailed parameter settings can also be made in the detailed setting mode, which covers all configurable functions.

Displays the image read from the scanner.

Adjustments – Adjustments can be made by following the on-screen instructions while viewing the image. Adjustment parameters can be saved as a file on the computer.

Advanced Setup Mode

While checking the image on the live screen, change the displayed parameter items so that the corresponding image is displayed. If you change the shutter speed, analogue gain, digital gain, black level, etc., the changes are reflected on the live screen in real time.

Symbol Print quality

The print quality of the symbol data read can be visually inspected item by item. (Overall Quality / Contrast/ Modulation / Fixed Data Damage / Decoding / Axis Irregularity / Grating Irregularity / Unused Error Correction)

ViT, an OCR configuration tool.

ViT is the software included with the MVF Config for configuring and checking the readings related to OCR.

With simple mouse and other operations, you can rewrite and save configuration parameters related to the OCR of the scanner; you can save ViT configuration parameters to your computer as a file or read configuration parameters from a saved file.

On-screen confirmation of symbol decoding results①, character reading results②, symbol print quality, collation judgement and overall judgement. A log of the reading data can be saved in a text file.

Introduction video

Product Specification

| model | MVF-500/MVF-500C(Cマウントレンズタイプ) |

|---|---|

| Interfaces | LAN(10BASE-T, 100BASE-TX, 1000BASE-T) RS-232C(1200bps ~ 115.2kbps) RS-485(For multi-drop connections)※1 |

| カメラ部 | |

| 撮影素子 | 2/3インチ CMOS モノクロ |

| 有効画素数 | 1920×1200(約230万画素) |

| 内蔵照明 | MVF-500 : 高輝度白色LED/ MVF-500C : - |

| 読み取り角度 | ピッチ(PITCH) :±35°/ スキュー(SKEW):±35°/ チルト(TILT): 360° |

| 読み取り距離 | MVF-500: DataMatrix:基本バー幅/セルサイズ 0.25mm 、近方 165mm、遠方 235mm 基本バー幅/セルサイズ 0.38mm 、近方 140mm、遠方 265mm QRコード:基本バー幅/セルサイズ 0.25mm 、近方 165mm、遠方 230mm 基本バー幅/セルサイズ 0.33mm 、近方 155mm、遠方 245mm MVF-500C(35mmレンズ使用時の参考値): |

| デジタル入力 | フォトカプラ絶縁 x1点 / 入力抵抗 : 1kΩ / OFF 電圧: 0~0.8V / ON 電圧 : 6~28V |

| デジタル出力 | フォトカプラ絶縁 x2点 / 最大定格 DC30V 50mA |

| 電源 | |

| 電源電圧 | DC24V±10% |

| 消費電流 | 待機時:約200mA , 動作時:約400mA |

| 耐環境性 | |

| 動作温度 | 0 ~ 40℃ |

| 動作湿度 | 35 ~ 85%R.H.(結露無きこと) |

| 保存温度 | -20 ~ 65℃ |

| 保存湿度 | 35 ~ 85%R.H.(結露無きこと) |

| 耐振動 | 10 ~ 55Hz 振幅1.5mm(全幅) / X,Y,Z各方向2時間 |

| 防塵防滴性能 | IP67 |

| 外形寸法 | MVF-500 : 54(H)x65(W)x100(D)mm(コネクタ、突起含まず) MVF-500C : 51.4(H)×65(W)×84.7(D)mm(コネクタ、突起含まず) |

| 質量 | MVF-500 : 430g以下 MVF-500C : 390g以下 |

| オプション | 画像処理機能(パターンマッチング、測長等)、照明:MLU-21-W、標準電源 : MPSU-3200-24U、マルチ接続用電源 : MPSU-500M |

※1 MVF-500マルチドロップ接続用です。上位機器へのインターフェースには使用できません。

Various downloads

Manuals, drivers and tools for this product are available for download. You will need to enter your customer details to download.